Ividiyo

Incazelo evamile

I-TP-TGXG-200 I-Automatic Bottle Capping Machine isetshenziselwa ukugoqa amakepisi emabhodleleni ngokuzenzakalelayo. Isetshenziswa kabanzi ekudleni, kwezemithi, ezimbonini zamakhemikhali nokunye. Awukho umkhawulo wokuma, impahla, usayizi wamabhodlela avamile nama-screw caps. Uhlobo lwe-capping oluqhubekayo lwenza i-TP-TGXG-200 ivumelane nesivinini somugqa wokupakisha ohlukahlukene. Lo mshini unezinhloso eziningi ngempela, osetshenziswa kabanzi futhi usebenza kalula. Uma kuqhathaniswa nohlobo oluvamile olusebenza ngezikhathi ezithile, i-TP-TGXG-200 isebenza kahle kakhulu, icindezela kakhulu, futhi ibangela ukulimala okuncane kumakepisi.

Isicelo

Umshini we-capping othomathikhi ungasetshenziswa kumabhodlela anama-screw caps ngobukhulu obuhlukahlukene, ubujamo kanye nezinto zokwakha.

A. Usayizi webhodlela

Ilungele amabhodlela anobubanzi obungu-20-120mm nobude obungu-60-180mm. Kodwa ingenziwa ngokwezifiso ngosayizi webhodlela ofanelekile ngale kwalolu hlu futhi.

B. Isimo sebhodlela

Umshini we-capping ozenzakalelayo ungasetshenziswa kumajamo ahlukahlukene njengesikwele esiyindilinga noma umumo oyinkimbinkimbi.

C. Ibhodlela nekepisi impahla

Noma ngabe iyini ipulasitiki yengilazi noma insimbi, umshini we-capping othomathikhi ungaphatha zonke.

D. Uhlobo lwesikulufa

Umshini we-capping ozenzakalelayo ungakulungela zonke izinhlobo ze-screw cap, njengepompo, isifutho, i-drop cap nokunye.

E. Imboni

Umshini we-capping othomathikhi ungajoyina zonke izinhlobo zezimboni kungakhathaliseki ukuthi i-powder, uketshezi, umugqa wokupakisha we-granule, noma ukudla, imithi, ikhemistri nanoma yimuphi omunye umkhakha. Nomaphi lapho kukhona ama-screw caps, kunomshini wokuvala ozenzakalelayo ozosebenza ngawo.

Inqubo yokwakha nokusebenza

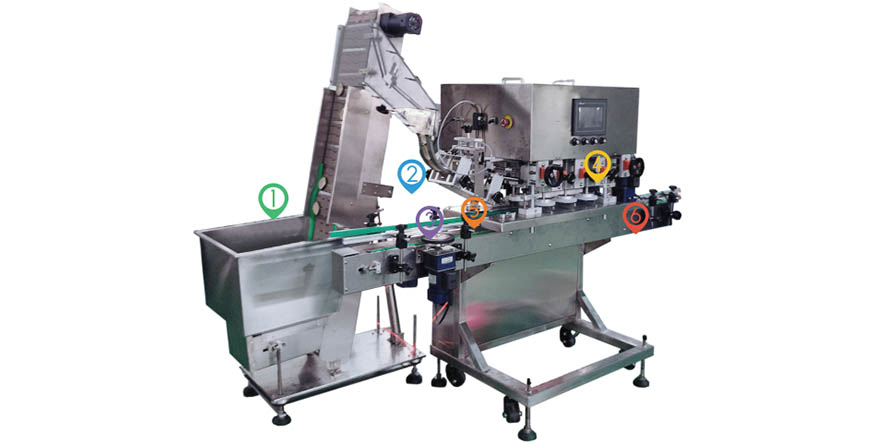

Iqukethe umshini we-capping kanye ne-cap feeder.

1. I-Cap feeder

2. Ukubeka ikepisi

3. Isihlukanisi sebhodlela

4. Capping amasondo

5. Ibhande lokubopha ibhodlela

6. Ibhande lokudlulisa ibhodlela

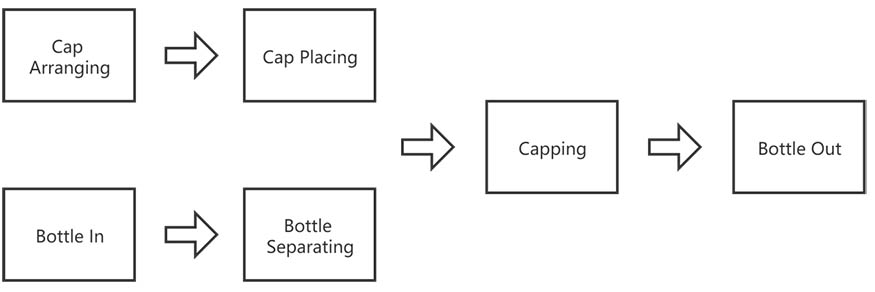

Okulandelayo kuyinqubo yokusebenza

Izici

■ Kusetshenziswa kakhulu emabhodleleni nasemakepisini ezinhlobonhlobo nempahla.

■ I-PLC&ukulawula isikrini, kulula ukuyisebenzisa.

■ Ukusebenza okulula nokulungisa kalula, yonga imithombo yabantu eyengeziwe kanye nezindleko zesikhathi.

■ Isivinini esiphezulu nesiguquguqukayo, esifanele zonke izinhlobo zomugqa wokupakisha.

■ Ukusebenza okuzinzile nokunemba okuphezulu.

■ Inkinobho eyodwa yokuqala umsebenzi iletha lula kakhulu.

■ Idizayini enemininingwane yenza umshini ube ngumuntu futhi uhlakaniphe.

■ Isilinganiso esihle ekubukeni komshini, ukwakheka kwezinga eliphezulu nokubukeka.

■ Umzimba womshini wenziwe nge-SUS 304, uhlangabezana nezinga le-GMP.

■ Zonke izingxenye zokuthintana ezinebhodlela nezivalo zenziwe ngezinto eziphephile zokudla.

■ Digital display screen ukukhombisa usayizi ibhodlela ezahlukene, okuzoba lula ukushintsha ibhodlela (Option).

■ Inzwa ye-Optronic yokukhipha amabhodlela afakwe amaphutha (Option).

■ Umshini wokuphakamisa izitebhisi ukuze ufakwe ngezivalo ngokuzenzakalelayo.

■ Ingxenye ewayo yesivalo ingasusa izivalo zamaphutha (ngokuphefumula komoya nokulinganisa isisindo).

■ Ibhande lokucindezela izivalo lithambekele, ngakho-ke lingakwazi ukulungisa isivalo endaweni efanele bese licindezela.

Uhlakaniphile

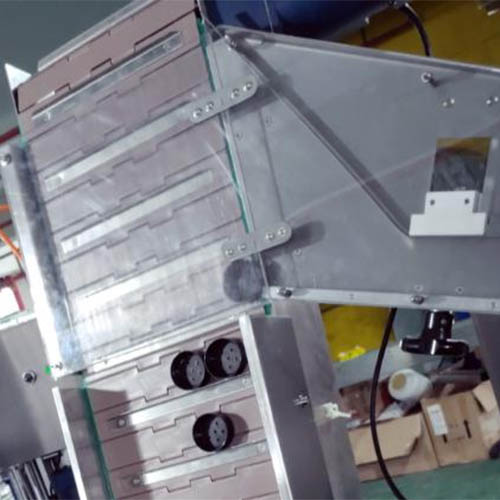

Sebenzisa umgomo webhalansi emaphakathi ehlukene ezinhlangothini ezimbili zekepisi, i-cap efanele kuphela engahanjiswa iye phezulu. Ikepisi eliya ohlangothini olungalungile lizowela phansi ngokuzenzakalelayo.

Ngemuva kokuthi isidluliseli silethe amakepisi ngaphezulu, isiphephetha siphephetha amakepisi abe yi-cap track.

Inzwa yephutha yezivalo ingathola izivalo ezihlanekezelwe kalula. Iphutha elizenzakalelayo lokukhipha ama-caps remover kanye nenzwa yebhodlela, finyelela umphumela omuhle we-capping

Isihlukanisi sebhodlela sizohlukanisa amabhodlela komunye nomunye ngokulungisa isivinini esinyakazayo samabhodlela endaweni yawo. Amabhodlela ayindilinga ngokuvamile adinga isihlukanisi esisodwa, futhi amabhodlela ayizikwele adinga izihlukanisi ezimbili eziphambene.

Ukuntuleka kokwazi kwedivayisi kulawula i-cap feeder esebenzayo futhi ime ngokuzenzakalelayo. Kunezinzwa ezimbili ezinhlangothini ezimbili ze-cap track, eyodwa ukuhlola ukuthi ithrekhi igcwele amakepisi, enye ukuhlola ukuthi ithrekhi ayinalutho.

Isebenza kahle

Isivinini esikhulu sokuthutha ibhodlela kanye ne-cap feeder singafinyelela ku-100 bpm, okuletha umshini isivinini esikhulu ukuze uvumelane nolayini wokupakisha ohlukahlukene.

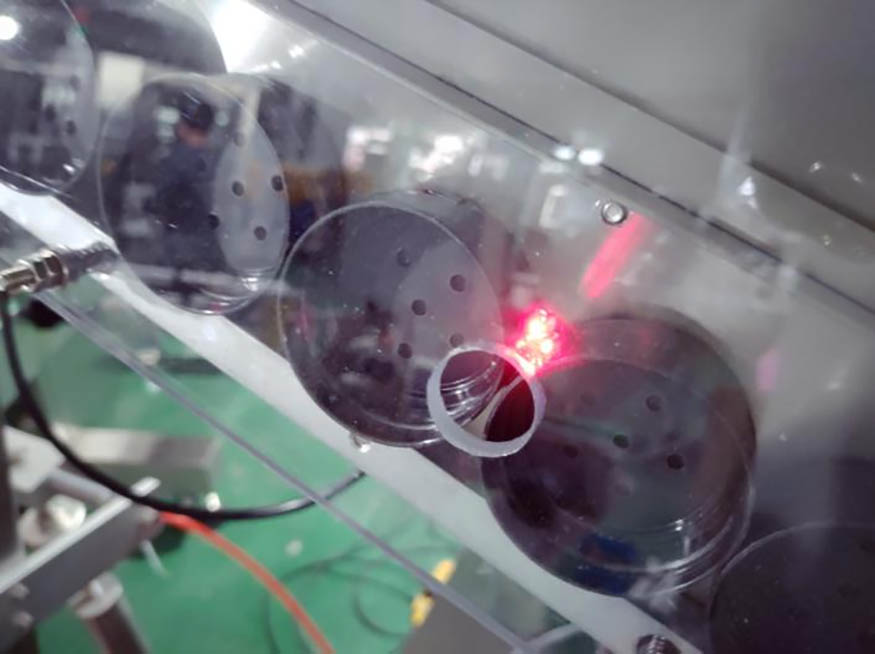

Amapheya amathathu amasondo ama-twist caps asuke ngokushesha. Ipheya ngayinye inomsebenzi othile. Ipheya yokuqala ingajika ibuyele emuva ukuze yenze amakepisi okubeka okunzima abe sendaweni yawo efanele. Kodwa bangakwazi ukwenza amakepisi ajike phansi ukuze afinyelele endaweni efanele ngokushesha kanye namasondo amapheya esibili lapho isivalo sijwayelekile. Amapheya esithathu alungisa kancane ukuze aqinise ikepisi, ngakho ijubane lawo lihamba kancane kuwo wonke amasondo.

Elula

Uma kuqhathaniswa nokulungiswa kwesondo lesandla kwabanye abahlinzeki, inkinobho eyodwa yokukhulisa noma ukwehlisa yonke idivayisi yokufaka i-capping kulula kakhulu.

Amaswishi amane ukusuka kwesokunxele ukuya kwesokudla asetshenziselwa ukulungisa isivinini sokuthutha ibhodlela, i-bottle clamp, i-cap climbing kanye nokuhlukaniswa kwamabhodlela. Ukudayela kungaqondisa opharetha ukuthi afinyelele isivinini esifanelekile sohlobo ngalunye lwephakheji kalula.

Amasondo esandla ukushintsha ibanga phakathi kwamabhande amabili okuqinisa amabhodlela kalula. Kunamasondo amabili emaphethelweni amabili ebhande lokubopha. Ukudayela kuholela opharetha ukuthi afike endaweni efanele lapho eshintsha osayizi bamabhodlela.

Ishintsha ukuze ilungise ibanga phakathi kwamasondo e-capping namakepisi. Ukusondela kwebanga, i-cap izoqina kakhulu. Ukudayela kusiza u-opharetha ukuthi athole ibanga elifaneleka kakhulu.

Ukusebenza okulula

I-PLC&ukulawula isikrini ngohlelo lokusebenza olulula, kwenza umsebenzi ube lula futhi usebenze kahle.

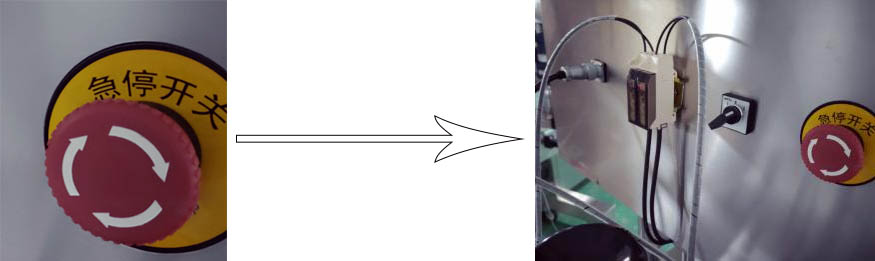

Inkinobho yesimo esiphuthumayo yokumisa umshini ngesikhathi esisodwa ngesikhathi esiphuthumayo, okugcina u-opharetha ehlala ephephile.

| TP-TGXG-200 Bottle Capping Machine | |||

| Amandla | 50-120 amabhodlela/min | Ubukhulu | 2100*900*1800mm |

| Amabhodlela ububanzi | Φ22-120mm (ngezifiso ngokuvumelana nemfuneko) | Ukuphakama kwamabhodlela | 60-280mm (ngezifiso ngokuvumelana nemfuneko) |

| Usayizi wesivalo | Φ15-120mm | Isisindo sengqikithi | 350kg |

| Isilinganiso esifanelekile | ≥99% | Amandla | 1300W |

| Material | Insimbi engagqwali 304 | Amandla kagesi | 220V/50-60Hz (noma ngokwezifiso) |

| Cha. | Igama | Umsuka | Ibhrendi |

| 1 | I-Invertor | I-Taiwan | I-Delta |

| 2 | Isikrini sokuthinta | China | I-TouchWin |

| 3 | Inzwa ye-Optronic | Korea | Ama-Autonics |

| 4 | CPU | US | I-ATMEL |

| 5 | I-Interface Chip | US | I-MEX |

| 6 | Ukucindezela Ibhande | Shanghai |

|

| 7 | I-Series Motor | I-Taiwan | TALIKE/GPG |

| 8 | SS 304 Uhlaka | Shanghai | I-BaoSteel |

Umshini we-capping othomathikhi ungasebenza ngomshini wokugcwalisa nomshini wokulebula ukuze wenze umugqa wokupakisha.

A. Ibhodlela unscrambler+auger filler+automatic capping machine+foil sealing machine.

B. Ibhodlela unscrambler+auger filler+automatic capping machine+foil sealing machine+labeling machine

IZISEKELO Ebhokisini

■ Incwadi yeziqondiso

■ Umdwebo kagesi nomdwebo wokuxhuma

■ Umhlahlandlela wokusebenza ngokuphepha

■ Iqoqo lezingxenye zokugqoka

■ Amathuluzi okunakekela

■ Uhlu lokucushwa (imvelaphi, imodeli, imininingwane, intengo)

1. Ukufakwa kwe-cap Elevator kanye nesistimu yokubeka i-cap.

(1) Ukufakwa kwe-cap yokuhlela kanye nenzwa yokuthola.

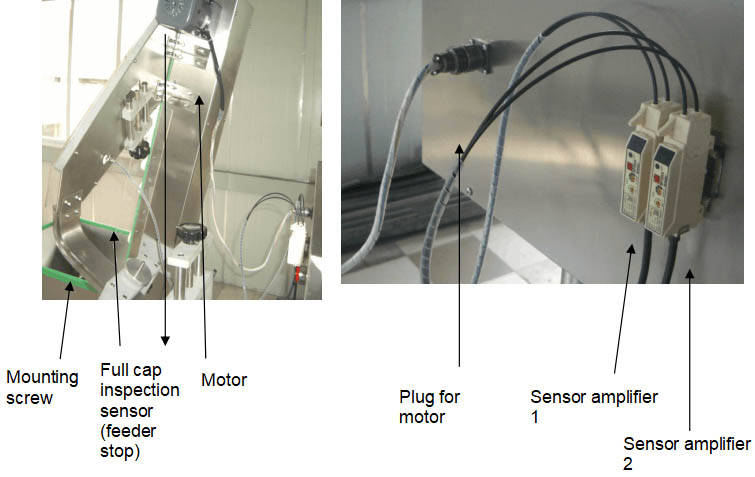

I-cap lift kanye nesistimu yokubeka ihlukanisiwe ngaphambi kokuthunyelwa, sicela ufake i-cap yokuhlela nokubeka uhlelo emshinini we-capping ngaphambi kokusebenzisa umshini. Sicela uxhume isistimu njengoba kukhonjisiwe ezithombeni ezilandelayo:

Ukuntula i-cap yokuhlola inzwa (isitobhi somshini)

a. Xhuma ithrekhi yokubeka i-cap kanye nerempu ngesikulufu sokukhweza.

b. Xhuma intambo yemoto ngepulaki ngakwesokudla kuphaneli yokulawula.

c. Xhuma inzwa yokuhlola ikhephu egcwele ne-sensor amplifier 1.

d. Xhuma inzwa yokuhlola yokuntula ne-sensor amplifier 2.

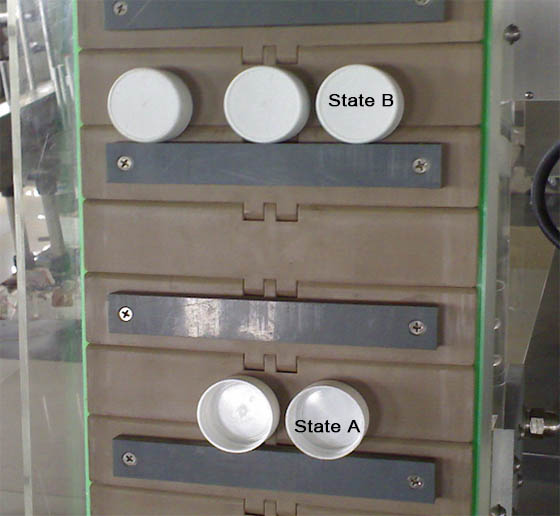

Lungisa i-engeli yeketango lokugibela ikhephu: I-engeli yeketango lokugibela ikhephu lilungisiwe ngokuya ngesampula lekepisi elinikezwe nguwe ngaphambi kokuthunyelwa. Uma kudingekile ukuthi ushintshe ukucaciswa kwekepisi (vele ushintshe usayizi, ungashintshi uhlobo lwekepisi), sicela ulungise i-engeli yeketango lokwenyuka ngesikulufu sokulungisa i-engeli kuze kube iketango likwazi ukudlulisa amakepisi ancike phezulu eketangoni elinohlangothi olungaphezulu. Inkomba njengokulandelayo:

Ikepisi kusimo A isiqondiso esilungile uma iketango lokugibela likhuphuka likhuphuka.

Ikepisi kusimo B izowela ithangi ngokuzenzakalelayo uma iketango liku-engeli efanele.

(2) Lungisa i-cap drop drop system (i-chute)

I-engeli ye-chute yokuwisa nendawo isivele isethiwe ngokwesampula enikeziwe. Ngokujwayelekile uma kungekho okunye ukucaciswa okusha kwebhodlela noma ikepisi, isilungiselelo akumele silungiswe. Futhi uma kukhona ukucaciswa okwengeziwe kunokucaciswa okungu-1 kwebhodlela noma ikepisi, iklayenti lidinga ukubhala into ekhontrakthi noma okunamathiselwe kwayo ukuze kuqinisekiswe ukuthi ukukhiqiza kushiya isikhala esanele sokulungiswa okwengeziwe. Indlela yokulungisa imi kanje:

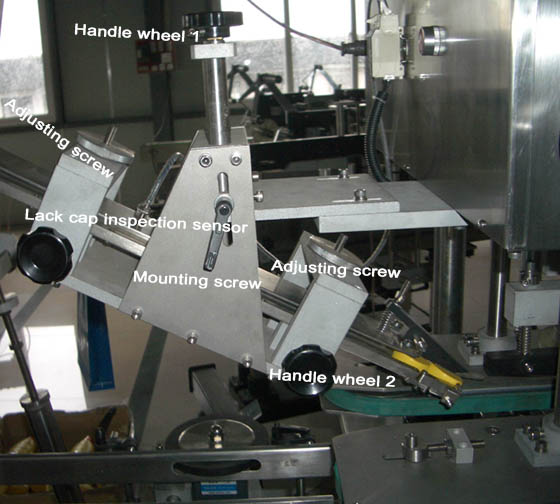

Lungisa ubude besistimu yokudonsa isivalo: Sicela ukhulule isikulufu sokukhweza ngaphambi kokuvula isondo lesibambo 1.

Isikulufu sokulungisa singalungisa ukuphakama kwesikhala se-chute.

Isondo lesibambo 2 (ezinhlangothini ezimbili) lingalungisa ububanzi besikhala se-chute.

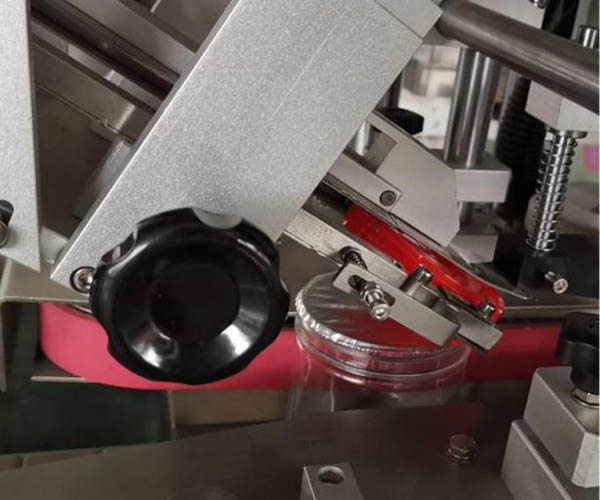

(3) Ukulungisa ingxenye yokucindezela ikepisi

Ikepisi lizovala umlomo webhodlela kusuka ku-chute ngokuzenzakalelayo lapho ibhodlela lidla endaweni yokucindezela ingxenye. Ingxenye yokucindezela i-cap nayo ingalungiswa ngenxa yokuphakama kwamabhodlela namakepisi. Kuzothinta ukusebenza kwe-capping uma ingcindezi ku-cap ingafaneleki. Uma indawo yengxenye yokucindezela i-cap iphezulu kakhulu, ukusebenza kokucindezela kuzothonywa. Futhi uma isikhundla siphansi kakhulu, ikepisi noma ibhodlela lizolimala. Ngokuvamile ubude bengxenye yokucindezela i-cap bulungisiwe ngaphambi kokuthunyelwa. Uma umsebenzisi edinga ukulungisa ubude, indlela yokulungisa imi kanje:

Sicela ukhulule isikulufu sokukhweza ngaphambi kokulungisa ubude bengxenye yokucindezela ikepisi.

Kukhona enye ingxenye yokucindezela i-cap enomshini ukuze ilingane ibhodlela elincane kakhulu, indlela yoshintsho ekhonjiswe ngayo kuvidiyo.

(4). Ukulungisa umfutho womoya ukuze ushaye ikepisi ku-chute.

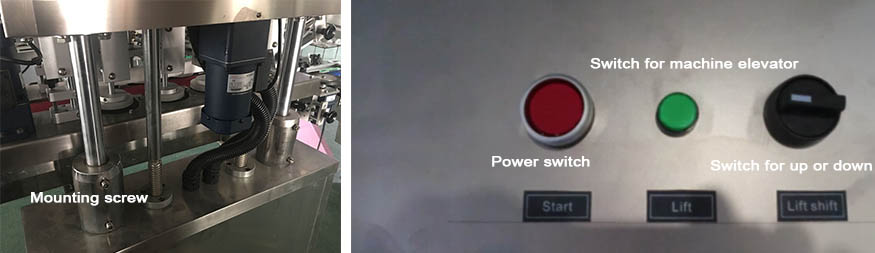

2. Ukulungisa ukuphakama kwezingxenye eziyinhloko sezizonke.

Ukuphakama kwezingxenye eziyinhloko ezifana nesakhiwo sokulungisa ibhodlela, isondo le-gum-elastic spin, ingxenye yokucindezela i-cap ingalungiswa iyonke nge-lifti yomshini. Inkinobho yokulawula yekheshi yomshini ingakwesokudla sephaneli yokulawula. Umsebenzisi kufanele akhulule isikulufu sokukhweza ezinsikeni ezimbili ezisekelayo ngaphambi kokuqala ikheshi lomshini.

u-ø usho phansi futhi u-ø usho phezulu. Ukuqinisekisa ukuthi ukuma kwamasondo aphendukayo kuhambisana namakepisi. Sicela uvale amandla esikheshi bese ubophela isikulufu sokukhweza ngemva kokulungiswa.

Phawula: Sicela ucindezele inkinobho yokuphakamisa (eluhlaza) ngaso sonke isikhathi uze uthole indawo efanele. Isivinini sekheshi sihamba kancane, sicela usilinde ngesineke.

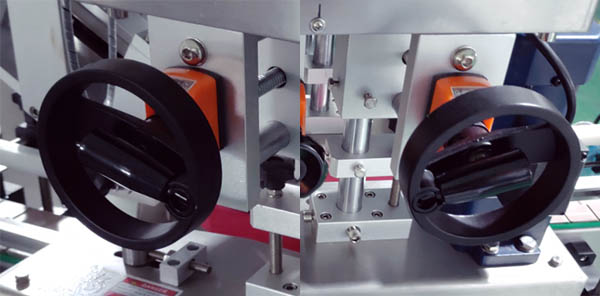

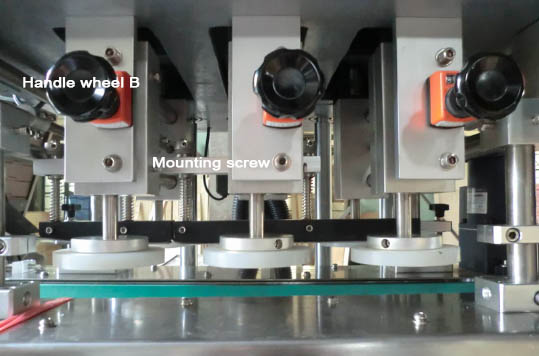

3. Lungisa isondo lokuphonswa kwe-gum-elastic (amapheya amathathu esondo elijikelezayo)

Ukuphakama kwesondo le-spin kulungiswa yi-lifti yomshini.

Ububanzi bepheya lesondo lokuphotha bulungiswa ngokuya ngobubanzi bekepisi.

Imvamisa ibanga eliphakathi kwesondo liba ngu-2-3mm ngaphansi kobubanzi bekepisi. I-opharetha ingalungisa ububanzi besondo lokuphotha ngesondo lesibambo B. (isondo ngalinye lesibambo lingalungisa isondo lokuphotha elihlobene).

Sicela ukhulule isikulufu sokukhweza ngaphambi kokulungisa isondo lesibambo B.

4. Ukulungisa isakhiwo sokulungisa ibhodlela.

Isikhundla sokulungisa ibhodlela singalungiswa ngokulungisa indawo yesakhiwo sokulungisa kanye ne-axis yesixhumanisi. Uma indawo yokulungisa iphansi kakhulu ebhodleleni, ibhodlela kulula ukulibeka ngesikhathi sokuncelisa noma ukumboza. Ngokuphambene nalokho uma indawo yokulungisa iphezulu kakhulu ebhodleleni, izophazamisa ukusebenza kahle kwamasondo aphendukayo. Qiniseka ukuthi umugqa omaphakathi we-conveyor kanye nezakhiwo zokulungisa amabhodlela zisemgqeni ofanayo ngemuva kokulungiswa.

Isondo lesibambo esiphendukayo A (ukuguqula isibambo ngezandla ezi-2 sindawonye) ukulungisa ibanga phakathi kwebhande lokulungisa ibhodlela. Ngakho-ke isakhiwo singalungisa kahle ibhodlela ngesikhathi sokucindezela.

Ukuphakama kwebhande lokulungisa ibhodlela kuvame ukulungiswa yi-elevator yomshini.

(Isixwayiso: I-Operator ingalungisa ubude bebhande lokulungisa ibhodlela kusiskopu esincanyana ngemva kokukhulula isikulufu sokukhweza ku-4 link shaft.)

Uma u-opharetha edinga ibhande lokulungisa elinyakazayo ebangeni elikhulu, sicela ulungise indawo yebhande ngemva kokukhulula isikulufu esingu-1 nesikulufu esingu-2 ndawonye, futhi uma u-opharetha edinga ukulungisa ubude bebhande ebangeni elincane, sicela ukhulule isikulufu esingu-1 kuphela, bese uvula iknobhu yokulungisa.

5. Ukulungisa isondo lokulungisa isikhala sebhodlela kanye nensimbi.

Umsebenzisi kufanele ashintshe indawo yesondo lokulungisa isikhala sebhodlela kanye nensimbi lapho eshintsha imininingwane yebhodlela. Isikhala phakathi kwesondo lokulungisa isikhala kanye nensimbi kufanele ibe ngu-2-3mm ngaphansi kobubanzi bebhodlela. Sicela uqiniseke ukuthi umugqa omaphakathi we-conveyor kanye nezakhiwo zokulungisa amabhodlela zikumugqa ofanayo ngemuva kokulungiswa.

Ukukhulula isikulufu sokulungisa singalungisa indawo yesondo lokulungisa isikhala sebhodlela.

Isibambo sokulungisa esixegayo singalungisa ububanzi bokuhlambalaza kuzo zombili izinhlangothi ze-conveyor.