Ukugcwalisa kanye ne-dosing kwenziwa ngomshini wokugcwalisa i-powder owomile. Impushana yekhofi, ufulawa kakolweni, ama-condiments, iziphuzo eziqinile, imithi yezilwane, i-dextrose, izithasiselo zempushana, i-talcum powder, ama-insecticide, udayi, nezinye izinto zifanele uhlobo ngalunye lomshini wokugcwalisa impuphu owomile. Imishini yokugcwalisa i-powder eyomile isetshenziswa ezimbonini ezahlukahlukene, kufaka phakathi ezemithi, ezolimo, amakhemikhali, ukudla nezokwakha.

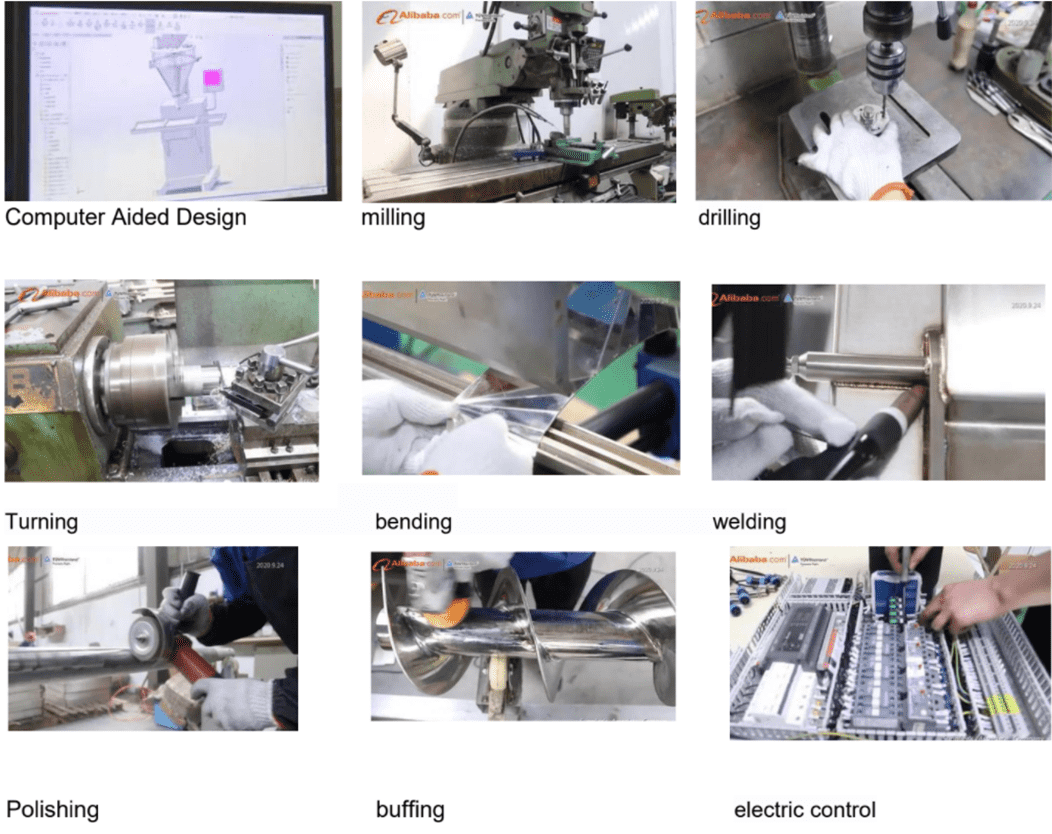

Senza ngokuncomekayo ezindaweni zezingxenye ezimaphakathi, ukunemba kokucubungula, nokuhlanganisa. Ukunemba kokucubungula nokuhlanganisa akubonakali emehlweni omuntu futhi ngeke kuqhathaniswe ngokushesha, kodwa kuzocaca ngesikhathi sokusetshenziswa.

Ukugxila okuphezulu:

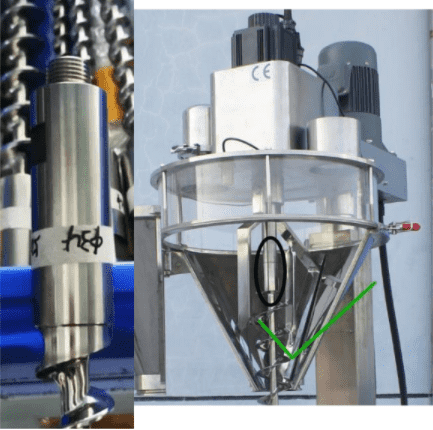

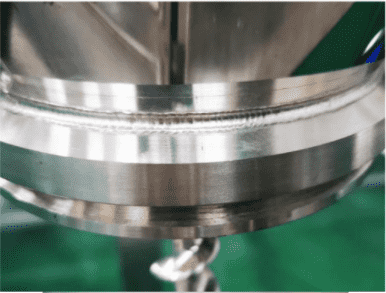

- ● Ukunemba ngeke kube sezingeni eliphezulu uma kungekho ukugxila okuphezulu ku-auger naku-shaft.

- ● Sasebenzisa i-brand shaft edumile emhlabeni wonke ye-auger kanye ne-servo motor.

Ukunemba kwemishini:

- ● Sisebenzisa umshini wokugaya ukuze sigaye ama-auger amancane, siqinisekise ukuthi unamabanga afanayo kanye nokuma okuhle.

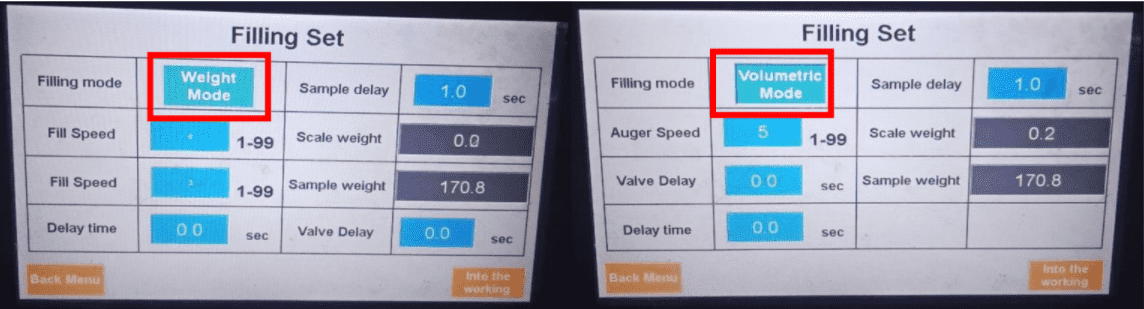

Izindlela ezimbili zokugcwalisa:

- ● Amamodi esisindo nevolumu angashintshwa.

Imodi Yesisindo: Ngaphansi kwepuleti yokugcwalisa kukhona iseli lomthwalo elikala isisindo sokugcwalisa ngesikhathi sangempela. Ukuze uzuze u-80% wesisindo sokugcwalisa esidingekayo, ukugcwaliswa kokuqala kuyashesha futhi kugcwaliswe ngobuningi. Ukugcwaliswa kwesibili kuhamba kancane futhi kunembile, kwengeza i-20% esele ngokwesisindo sokugcwalisa kokuqala. Ukunemba kwemodi yesisindo kuphezulu, kodwa ijubane lihamba kancane.

Imodi yevolumu: Ivolumu yempushana encishisiwe ngokuphendula isikulufu umzuliswano owodwa ilungisiwe. Isilawuli sizobona ukuthi zingaki izijiko ezidinga ukwenziwa isikulufu ukuze sifinyelele isisindo sokugcwalisa esifunekayo.

Izici Eziyinhloko:

-Ukuqinisekisa ukunemba kokugcwalisa okuphelele, kusetshenziswa isikulufu se-lathing auger.

Ukulawulwa kwe-PLC nesibonisi sesikrini sokuthinta kuyasetshenziswa.

- Ukuqinisekisa imiphumela enembile, i-servo motor inika amandla isikulufu.

-I-hopper ehlukanisiwe ingahlanzwa ngokushesha ngaphandle kwesidingo sanoma imaphi amadivaysi.

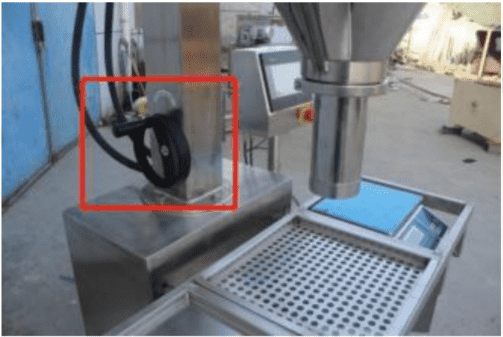

- Insimbi engagqwali egcwele engu-304 engalungiselelwa ukuthi igcwale i-semi-auto ngokushintshwa kwe-pedal.

- Impendulo yesisindo kanye nethrekhi yesilinganiso ezingxenyeni, ezixazulula izinselele zokugcwalisa ukuhluka kwesisindo ngenxa yokuhlukahluka kokuqina kwezingxenye.

-Gcina izilungiselelo zefomula ezingu-20 ukuze zisetshenziswe kamuva emshinini.

-Izinto ezisetshenziswayo ezisukela kumpushana ocolekile kuye kugranule nezisindo ezahlukene zingapakishwa ngokushintsha izingcezu ze-auger.

-I-interface yomsebenzisi itholakala ngezilimi ezihlukahlukene.

Izinhlobo Ezihlukene Zomshini Wokugcwalisa I-Powder Eyomile

1.Ithebula ledeskithophu

Imisebenzi yokugcwalisa ingenziwa ngohlobo lwetafula ledeskithophu lomshini wokugcwalisa i-powder owomile. Kusetshenzwa mathupha ngokubeka ibhodlela noma isikhwama epuletini ngaphansi kwesigcwalisi bese sisusa ibhodlela noma isikhwama ngemva kokugcwalisa. Inzwa yemfoloko enyakazayo noma inzwa ye-photoelectric ingasetshenziswa ukuthola izinga lempushana. Umshini wokugcwalisa i-powder owomile uyimodeli encane kakhulu yelabhorethri.

Ukucaciswa

| Imodeli | I-TP-PF-A10 | I-TP-PF-A11 TP-PF A11S | I-TP-PF-A14 TP-PF-A14S | ||||||

| Lawulauhlelo | I-PLC &Isikrini sokuthinta | I-PLC nesikrini sokuthinta | I-PLC nesikrini sokuthinta | ||||||

| I-Hopper | 11L | 25L | 50L | ||||||

| UkupakishaIsisindo | 1-50g | 1-500g | 10-5000 g | ||||||

| Isisindoumthamo | Nge-auger | Nge-auger Ngeseli yokulayisha | Nge-auger Ngeseli yokulayisha | ||||||

| IsisindoImpendulo | Ngesilinganiso esingaxhunyiwe ku-inthanethi (esithombeni) | Ngokungaxhunyiwe ku-inthanethiisikali ( ngesisindoisithombe) impendulo | Ngokungaxhunyiwe ku-inthanethiisikali ( ngesisindoisithombe) impendulo | ||||||

| UkupakishaUkunemba | ≤ 100g, ≤±2% | ≤ 100g, ≤±2%; 100 -500g, ≤±1% | ≤ 100g, ≤±2%; 100 – 500g, ≤±1%;>500g, ≤±0.5% | ||||||

| Isivinini sokugcwalisa | 20 - 120 izikhathi ngomzuzu | 20 - 120 izikhathi ngomzuzu | 20 - 120 izikhathi ngomzuzu | ||||||

| AmandlaUkunikezela | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz | ||||||

| Amandla Aphelele | 0.84KW | 0.93 kW | 1.4KW | ||||||

| Isisindo Esiphelele | 90kg | 160kg | 260kg | ||||||

| SekukonkeUbukhulu | 590×560×1070mm | 800×790×1900mm | 1140×970×2200mm | ||||||

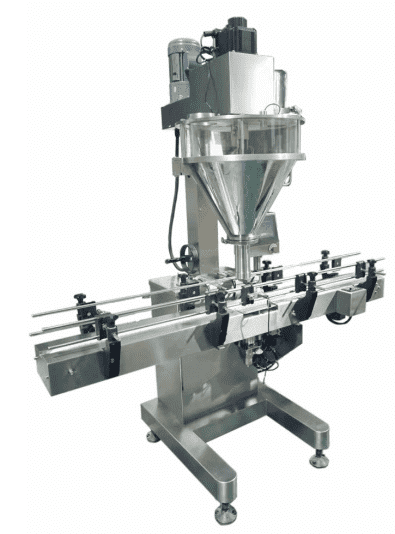

2.Uhlobo oluzenzakalelayo

Uhlobo lwe-Semi-automatic lomshini wokugcwalisa i-powder owomile lusebenza kahle ekugcwaliseni. Isebenza mathupha ngokubeka ibhodlela noma isikhwama epuletini ngaphansi kwesigcwalisi bese isusa ibhodlela noma isikhwama uma sesigcwalisiwe. Inzwa yemfoloko yokulungisa noma inzwa ye-photoelectric ingasetshenziswa njengenzwa. Ungaba nomshini omncane wokugcwalisa i-powder owomile kanye namamodeli ajwayelekile, kanye namamodeli asezingeni eliphezulu omshini wokugcwalisa i-powder owomile we-powder.

Ukucaciswa

| Imodeli | I-TP-FF-A11 TP-PF A11N | I-TP-PF-A11S TP-PF A11NS | I-TP-FF-A14 TP-PF-A14N |

| Lawula uhlelo | I-PLC nesikrini sokuthinta | I-PLC nesikrini sokuthinta | I-PLC nesikrini sokuthinta |

| I-Hopper | 25L | 25L | 50L |

| Ukupakisha Isisindo | 1-500g | 1-500g | 1-5000g |

| Isisindo umthamo | Nge-auger Ngeseli yokulayisha | Nge-auger Ngeseli yokulayisha | Nge-auger Ngeseli yokulayisha |

| Isisindo Impendulo | Ngokungaxhunyiwe ku-inthanethi isikali ( ngesisindo isithombe) impendulo | Ngokungaxhunyiwe ku-inthanethi isikali ( ngesisindo isithombe) impendulo | Ngokungaxhunyiwe ku-inthanethi isikali ( ngesisindo isithombe) impendulo |

| Ukupakisha Ukunemba | ≤ 100g, ≤±2%; 100 - 500g, ≤±1% | ≤ 100g, ≤±2%; 100 - 500g, ≤±1% | ≤ 100g, ≤±2%; 100 – 500g, ≤±0.5% |

| Isivinini sokugcwalisa | 20 - 120 izikhathi ngomzuzu | 20 - 120 izikhathi ngomzuzu | 20 - 120 izikhathi ngomzuzu |

| Amandla Ukunikezela | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Amandla Aphelele | 0.93 kW | 0.93 kW | 1.4KW |

| Isisindo Esiphelele | 160kg | 160kg | 260kg |

| Sekukonke Ubukhulu | 800×790×1900mm | 800×790×1900mm | 1140×970×2200mm |

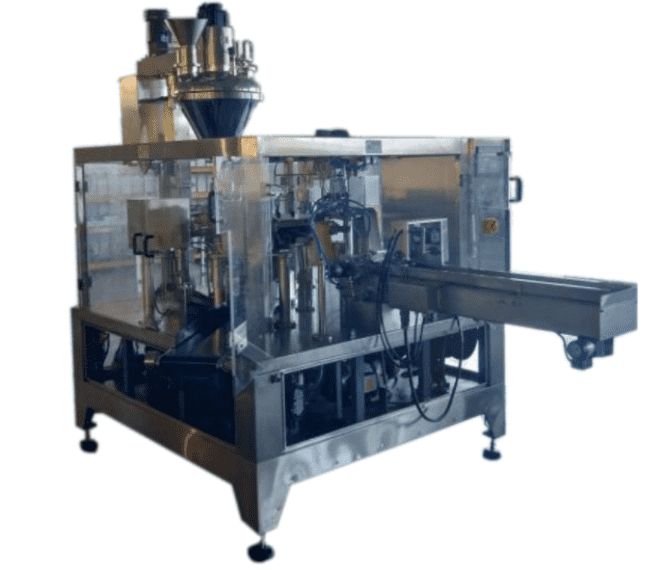

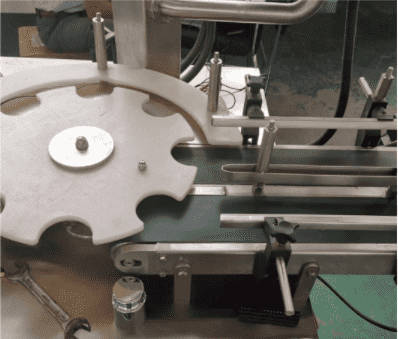

3.Uhlobo lolayini oluzenzakalelayo

Umshini wokugcwalisa i-powder owomile onemigqa othomathikhi wenza kahle ukudosa nokugcwalisa. Isivalo sebhodlela sibamba amabhodlela emuva ukuze umnikazi webhodlela akwazi ukuphakamisa ibhodlela ngaphansi kwesigcwalisi, futhi umthumeli uhambisa ibhodlela ngokuzenzakalelayo. Ngemva kokuba amabhodlela egcwalisiwe, isihambisi siwahambisa phambili ngokuzenzakalelayo. Iphelele kubasebenzisi abanobukhulu obuhlukile bokupakisha ngoba ingakwazi ukuphatha osayizi abahlukene bebhodlela emshinini owodwa. Inzwa yemfoloko kanye nenzwa ye-photoelectric yizinhlobo ezimbili zezinzwa ezifinyelelekayo. Ingahlanganiswa ne-powder feeder, i-powder mixer, umshini we-capping, nomshini wokulebula ukuze kwakhiwe umugqa wokupakisha ozenzakalelayo.

Ukucaciswa

| Imodeli | I-TP-PF-A21 | I-TP-PF-A22 |

| Isistimu yokulawula | I-PLC nesikrini sokuthinta | I-PLC nesikrini sokuthinta |

| I-Hopper | 25L | 50L |

| Ukupakisha Isisindo | 1 - 500 g | 10-5000g |

| Ukulinganisa isisindo | Nge-auger | Nge-auger |

| Isisindo Impendulo | ≤ 100g, ≤±2%; 100 – 500g, ≤±1% | ≤ 100g, ≤±2%; 100 - 500g, ≤±1%; ≥500g,≤±0.5% |

| Ukunemba kokupakisha | 40 - 120 izikhathi ngomzuzu | 40 - 120 izikhathi ngomzuzu |

| Isivinini sokugcwalisa | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Amandla Aphelele | 1.2 KW | 1.6 kW |

| Isisindo Esiphelele | 160kg | 300kg |

| Ubukhulu Sebonke | 1500×760×1850mm | 2000×970×2300mm |

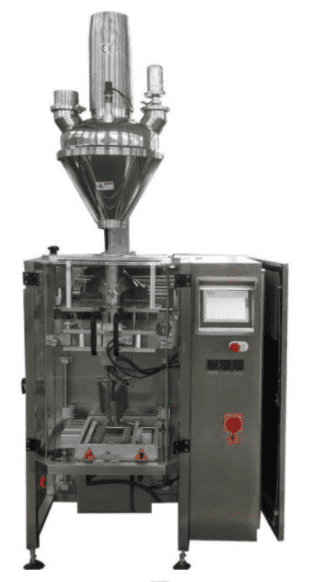

4.Uhlobo lwe-rotary oluzenzakalelayo

Uhlobo lwe-rotary olusheshayo olusheshayo lusetshenziselwa ukufaka impushana emabhodleleni. Ngenxa yokuthi isondo lebhodlela lingakwazi ukufaka ububanzi obulodwa kuphela, lolu hlobo lomshini wokugcwalisa i-powder owomile lungcono kakhulu kumakhasimende anebhodlela elilodwa noma amabili ububanzi kuphela. Ngokuvamile, ijubane nokunemba kohlobo lwe-liner oluzenzakalelayo lukhulu. Ukwengeza, uhlobo lwe-rotary oluzenzakalelayo lunamandla okukala kanye nokwenqaba ku-inthanethi. I-filler izogcwalisa i-powder ngesikhathi sangempela ngokusekelwe esisindweni sokugcwalisa, ngendlela yokwenqaba eqaphela futhi ilahle isisindo esingafanelekile. Ikhava yomshini iyintandokazi yomuntu siqu.

Ukucaciswa

| Imodeli | I-TP-PF-A32 | I-TP-PF-A31 |

| Isistimu yokulawula | I-PLC nesikrini sokuthinta | I-PLC nesikrini sokuthinta |

| I-Hopper | 35L | 50L |

| Ukupakisha Isisindo | 1-500g | 10-5000g |

| Ukulinganisa isisindo | Nge-auger | Nge-auger |

| Usayizi wesitsha | Φ20~100mm ,H15~150mm | Φ30~160mm ,H50~260mm |

| Ukunemba kokupakisha | ≤ 100g, ≤±2% 100 – 500g, ≤±1% | ≤ 100g, ≤±2%; 100 – 500g, ≤±1% ≥500g,≤±0.5% |

| Isivinini sokugcwalisa | 20 - 50 izikhathi ngomzuzu | 20 - 40 izikhathi ngomzuzu |

| Ukunikezwa kwamandla kagesi | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Amandla Aphelele | 1.8KW | 2.3 KW |

| Isisindo Esiphelele | 250kg | 350kg |

| Ubukhulu Sebonke | 1400*830*2080mm | 1840×1070×2420mm |

5.Uhlobo lwesikhwama esikhulu

Lesi sikhwama esikhulu senzelwe ukubamba isamba esikhulu sempahla enesisindo esingaphezu kuka-5kg kodwa esingaphansi kuka-50kg. Lo mshini ungenza izilinganiso, ukugcwalisa kabili, umsebenzi okhuphukayo, kanye neminye imisebenzi. Okulandelayo kusekelwe empendulweni yenzwa yesisindo. Ilungele ukugcwalisa izimpushana ezinhle ezidinga ukupakishwa okunembile, njengezithasiselo, i-carbon powder, isicisha-mlilo impushana eyomile, nezinye izimpushana ezinhle, njengezinye izinhlobo zemishini yokugcwalisa impushana eyomile.

Ukucaciswa

| Imodeli | I-TP-PF-B11 | I-TP-PF-B12 |

| Isistimu yokulawula | I-PLC nesikrini sokuthinta | I-PLC nesikrini sokuthinta |

| I-Hopper | Ukunqamula hopper okusheshayo 70L | Ukunqamula hopper okusheshayo 100L |

| Ukupakisha Isisindo | 100-10 kg | 1-50kg |

| Imodi yokuphuza | Ngesisindo se-inthanethi; Ukugcwalisa ngokushesha futhi kancane | Ngesisindo se-inthanethi; Ukugcwalisa ngokushesha futhi kancane |

| Ukunemba kokupakisha | 100-1000g, ≤±2g; ≥1000g,±0.2% | 1 – 20kg, ≤±0.1-0.2%, >20kg, ≤±0.05-0.1% |

| Isivinini sokugcwalisa | 5 - 30 izikhathi ngomzuzu | 2– 25 izikhathi ngomzuzu |

| Ukunikezwa kwamandla kagesi | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Amandla aphelele | 2.7KW | 3.2 KW |

| Isisindo esiphelele | 350kg | 500kg |

| Ubukhulu Sebonke | 1030×850×2400mm | 1130×950×2800mm |

Uhlu Lokucushwa

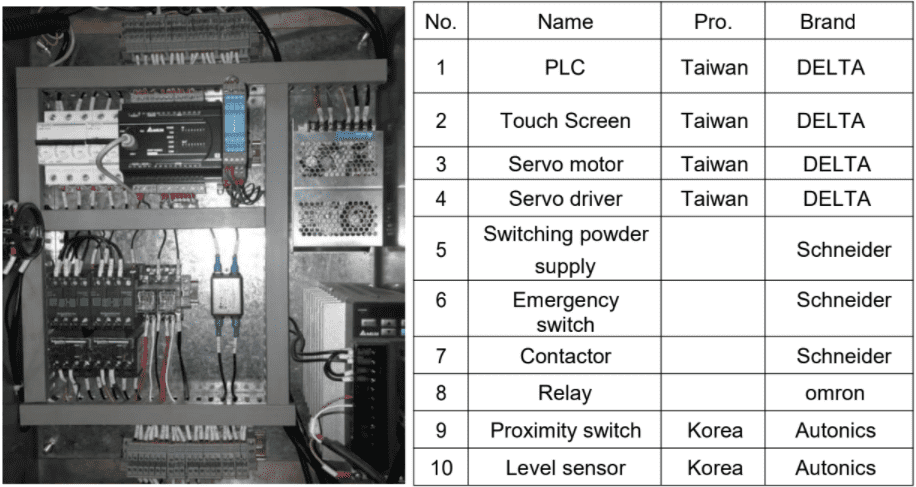

| Cha. | Igama | Ukucaciswa | UPro. | Ibhrendi |

| 1 | Insimbi engagqwali | I-SUS304 | China | |

| 2 | Isikrini sokuthinta | EJalimane | Siemens | |

| 3 | I-Servo motor | I-Taiwan | I-Delta | |

| 4 | Umshayeli we-Servo | I-ESDA40C-TSB152B27T | I-Taiwan | I-TECO |

| 5 | I-Agitator motor | 0.4kw,1:30 | I-Taiwan | CPG |

| 6 | Shintsha | Shanghai | ||

| 7 | Ukushintsha kwesimo esiphuthumayo | Schneider | ||

| 8 | Hlunga | Schneider | ||

| 9 | Oxhumana naye | Wenzhou | CHINT | |

| 10 | I-Relay eshisayo | Wenzhou | CHINT | |

| 11 | Isihlalo se-Fuse | I-RT14 | Shanghai | |

| 12 | I-Fuse | I-RT14 | Shanghai | |

| 13 | I-Relay | u-Omron | ||

| 14 | Ukushintsha ukunikezwa kwamandla | Changzhou | Chenglian | |

| 15 | I-Proximity switch | I-BR100-DDT | Korea | Ama-Autonics |

| 16 | Inzwa yeleveli | Korea | Ama-Autonics |

Isistimu yokupakisha i-powder

Umshini wokupakisha we-powder wenziwa lapho umshini wokugcwalisa i-powder owomile nomshini wokupakisha uhlanganiswa. Ingasetshenziswa ngokuphathelene nomshini wokugcwalisa isikhwama sefilimu ye-roll kanye nomshini wokuvala, umshini wokupakisha we-micro doypack, umshini wokupakisha isikhwama esijikelezayo, noma umshini wokupakisha owenziwe ngaphambili.

Uhlu Lokucushwa Lomshini Wokugcwalisa Impuphu Eyomile

Imininingwane Yomshini Wokugcwalisa Impuphu Eyomile

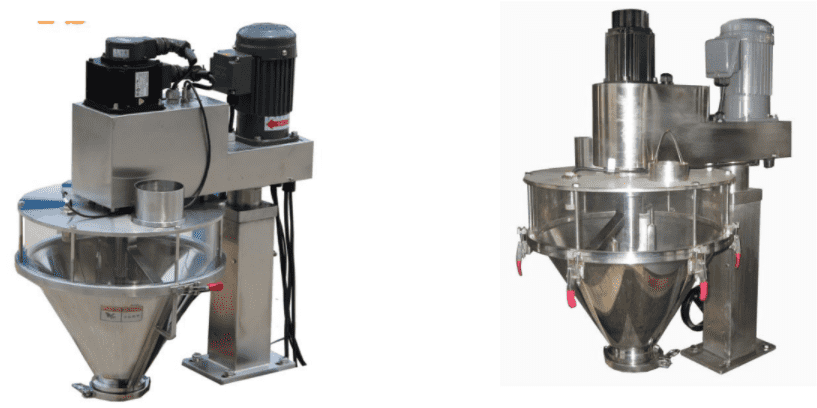

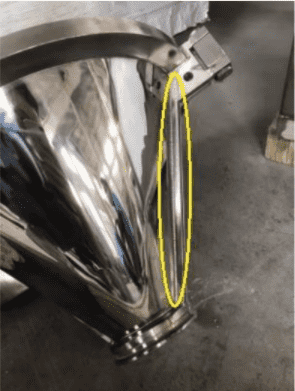

● I-Hopper Yokuzikhethela

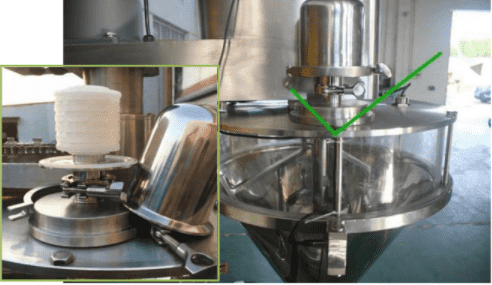

I-hopper evulekile isigamu

Le hopper yokuhlukanisa ileveli kulula ukuyihlanza nokuyivula.

I-hopper elengayo

Hlanganisa i-hopper ifanele impushana ecolekile futhi alikho igebe engxenyeni engezansi ye-hopper.

● Imodi yokugcwalisa

Isisindo nevolumu izindlela ziyashintsha.

Imodi yevolumu

Umthamo wempushana oncishisiwe ngokuphendula isikulufu umjikelezo owodwa ulungisiwe. Isilawuli sizobona ukuthi zingaki izijiko ezidinga ukwenziwa isikulufu ukuze sifinyelele isisindo sokugcwalisa esifunekayo.

Umshini wokugcwalisa i-Auger powderukulungisa indlela

Uhlobo lwesikulufu

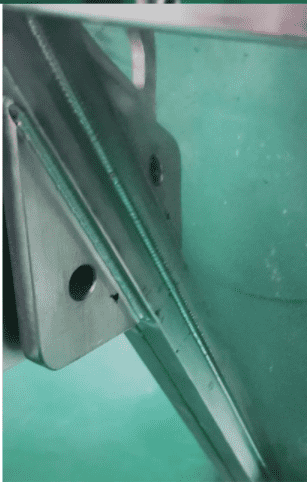

Azikho izikhala ngaphakathi lapho impushana ingase icashe khona, futhi kulula ukuyihlanza.

Umshini wokugcwalisa i-Auger powderisondo lesandla

Kuyafaneleka ukugcwalisa amabhodlela nezikhwama zokuphakama okuhlukene. Ukuphakamisa nokwehlisa isigcwalisi ngokuphendula isondo lesandla. Futhi isibambi sethu sikhulu futhi sihlala isikhathi eside.

Umshini wokugcwalisa i-Auger powderukucubungula

Okushiselwe ngokugcwele okuhlanganisa unqenqema lwe-hopper futhi kulula ukuyihlanza.

Umshini wokugcwalisa i-Auger powdermotor base

Wonke umshini, okuhlanganisa isisekelo nesibambi semoto, wenziwe nge-SS304, eqinile futhi esezingeni eliphakeme.

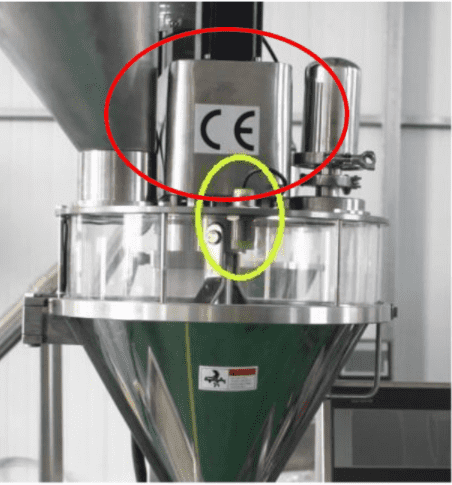

Umshini wokugcwalisa i-Auger powderindawo yomoya

Lo mklamo okhethekile owokuvimbela uthuli ukuthi luwele ku-hopper. Kulula ukuhlanza futhi izinga eliphezulu.

Umshini wokugcwalisa i-Auger powderamabhande amabili okukhiphayo

Ibhande elilodwa liqoqa amabhodlela afanelekayo anesisindo, kanti elinye ibhande liqoqa amabhodlela angafaneleki anesisindo.

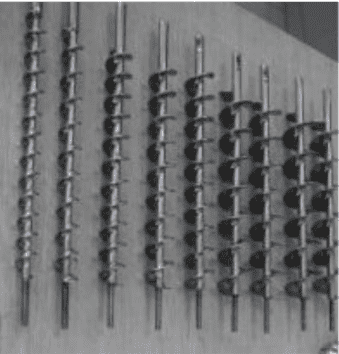

Umshini wokugcwalisa i-Auger powderosayizi abahlukene be-metering auger kanye nemibhobho yokugcwalisa

Yomileukulungiswa komshini wokugcwalisa i-powder

● Faka amafutha amancane kanye ezinyangeni ezintathu noma ezine.

● Faka iGrisi kancane ku-stir motor chain kanye ezinyangeni ezintathu noma ezine.

● Umucu wokuvala ezinhlangothini zombili zomgqomo wezinto ezibonakalayo ungase uguge cishe ngemva konyaka owodwa. Zishintshe uma kudingeka.

● Umcu wokuvala kuzo zombili izinhlangothi ze-hopper ungase uguge cishe ngemva konyaka owodwa. Zishintshe uma kudingeka.

● Hlanza umgqomo wezinto ezibonakalayo kusenesikhathi.

● Hlanza i-hopper ngesikhathi.

Yomileumshini wokugcwalisa i-powderosayizi kanye nezilinganiso zesisindo sokugcwalisa ezihlobene

Osayizi Bendebe kanye Nobubanzi Bokugcwalisa

| Oda | Indebe | Ububanzi Bangaphakathi | Ububanzi bangaphandle | Ibanga Lokugcwalisa |

| 1 | 8# | 8 | 12 |

|

| 2 | 13# | 13 | 17 |

|

| 3 | 19# | 19 | 23 | 5-20g |

| 4 | 24# | 24 | 28 | 10-40 g |

| 5 | 28# | 28 | 32 | 25-70g |

| 6 | 34# | 34 | 38 | 50-120g |

| 7 | 38# | 38 | 42 | 100-250 g |

| 8 | 41# | 41 | 45 | 230-350g |

| 9 | 47# | 47 | 51 | 330-550g |

| 10 | 53# | 53 | 57 | 500-800 g |

| 11 | 59# | 59 | 65 | 700-1100 g |

| 12 | 64# | 64 | 70 | 1000-1500 g |

| 13 | 70# | 70 | 76 | 1500-2500 g |

| 14 | 77# | 77 | 83 | 2500-3500g |

| 15 | 83# | 83 | 89 | 3500-5000g |

Ungaxhumana nathi futhi sizokusiza ukuthi ukhethe usayizi ofanele womshini wakho wokugcwalisa i-powder owomile oyifunayo.

Yomileimikhiqizo yesampula yomshini wokugcwalisa i-powder

Yomileukucubungula umshini wokugcwalisa i-powder

Umbukiso Wemboni

Singabahlinzeki bomshini wokupakisha ochwepheshe abasebenza ngokukhethekile emikhakheni yokuklama, ukukhiqiza, ukusekela, kanye nokusevisa ulayini ophelele wemishini yezinhlobo ezahlukene zoketshezi, impushana, nemikhiqizo eyimbudumbudu. Sasebenzisa ukukhiqiza imboni yezolimo, imboni yamakhemikhali, imboni yokudla, kanye nezinkambu zamakhemisi, nokunye okuningi. Saziwa kakhulu ngomqondo wokuklama othuthukile, ukwesekwa kwamasu ochwepheshe kanye nemishini yekhwalithi ephezulu.

I-Tops-Group ibheke ngabomvu ukukunikeza isevisi emangalisayo kanye nemikhiqizo ehlukile yemishini esekelwe kumanani ayo ebhizinisi we-TRUST, QUALITY, kanye ne-INOVATION! Sonke ngokubambisana masidale ubudlelwano obubalulekile futhi sakhe ikusasa eliphumelelayo.