Incazelo:

Imishini yokufaka amabhodlela isikulufa amakepisi emabhodleleni ngokuzenzakalelayo. Lokhu kuklanyelwe ukusetshenziswa emugqeni wokupakisha. Ngokungafani nomshini we-capping ojwayelekile ojwayelekile, lona usebenza ngokuqhubekayo. Lo mshini usebenza kahle kakhulu kunokuvala izikhawu ngoba ucindezela izivalo ngokuqinile futhi ubangela ukulimala okuncane kuzivalo. Izimboni zokudla, ezemithi, namakhemikhali manje ziyisebenzisa kakhulu.

Imininingwane:

Uhlakaniphile

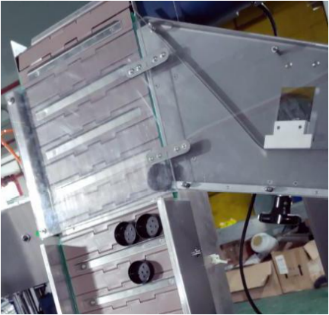

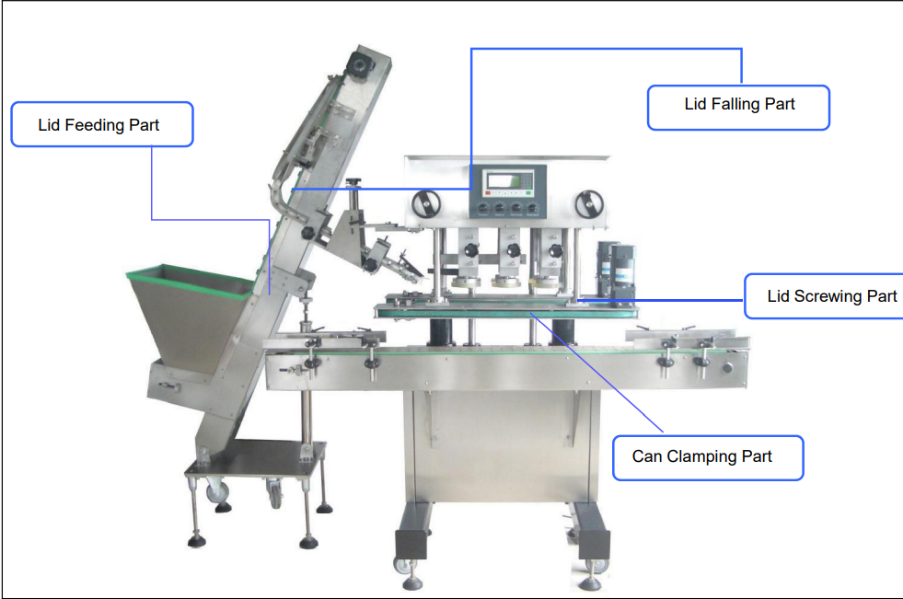

Ngemuva kokuthi isidluliseli sithuthe amakepisi ukuya phezulu, isiphephetha siphephetha amakepisi ku-cap track.

Ikepisi ayinalo idivayisi yokubona ilawula ukusebenza okuzenzakalelayo nokuma kwe-cap feeder. Ezinhlangothini eziphikisanayo ze-cap track kukhona izinzwa ezimbili, eyodwa eyokunquma ukuthi ithrekhi igcwele ama-caps kanye neyokunquma ukuthi ithrekhi ayinalutho.

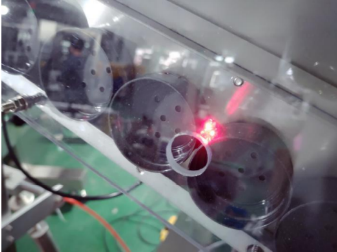

Inzwa yesivalo engalungile ingathola kalula izivalo ezihlanekezelwe. Ukuze kukhiqizwe umphumela ogculisayo wokubamba, isikhiphi se-caps yephutha nenzwa yebhodlela zisebenza ndawonye.

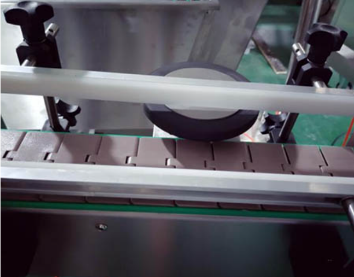

Isihlukanisi sebhodlela sihlukanisa amabhodlela ngokushintsha isivinini ahamba ngaso endaweni yawo. Emabhodleleni ayindilinga, isihlukanisi esisodwa ngokuvamile siyadingeka, kanti amabhodlela ayisikwele adinga izihlukanisi ezimbili.

Isebenza kahle

I-conveyor yebhodlela kanye ne-cap feeder ingasebenza ngesivinini esiphezulu esingu-100 bpm, okuvumela umshini ukusekela izinqubo zokupakisha ezihlukahlukene.

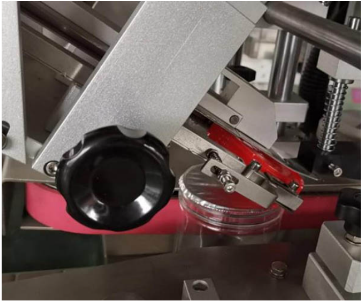

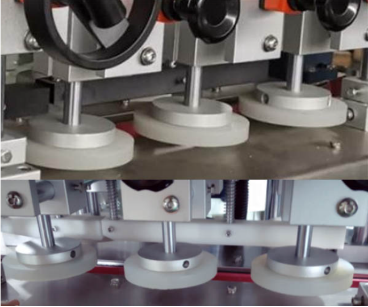

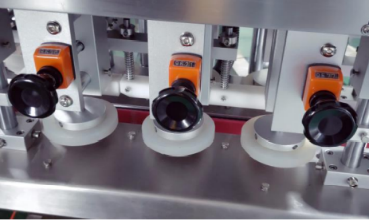

Amapheya amathathu ama-twist caps amasondo asuka ngokushesha; umbhangqwana wokuqala ungahlehliswa ukuze usheshe ubeke amakepisi endaweni efanele.

Elula

Ngenkinobho eyodwa nje, ungashintsha ubude besistimu yokufaka i-capping ephelele.

Amasondo angasetshenziswa ukulungisa ububanzi be-bottle-capping track.

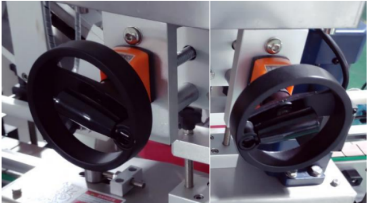

Shintsha isivinini sepheya ngalinye lamasondo okuvala ngokuphenyisisa iswishi.

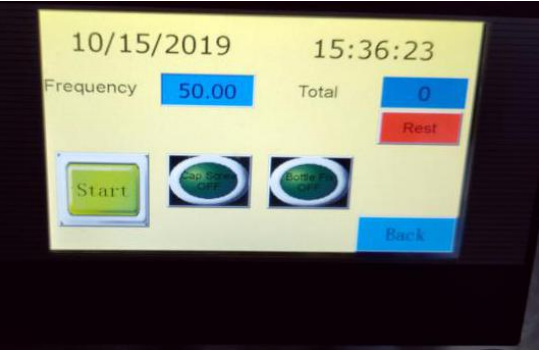

Kulula ukusebenza

Umsebenzi wenziwa ube lula futhi uphumelele ngokwengeziwe ngokusebenzisa i-PLC kanye nesistimu yokulawula isikrini sokuthinta nge-software yokusebenza elula.

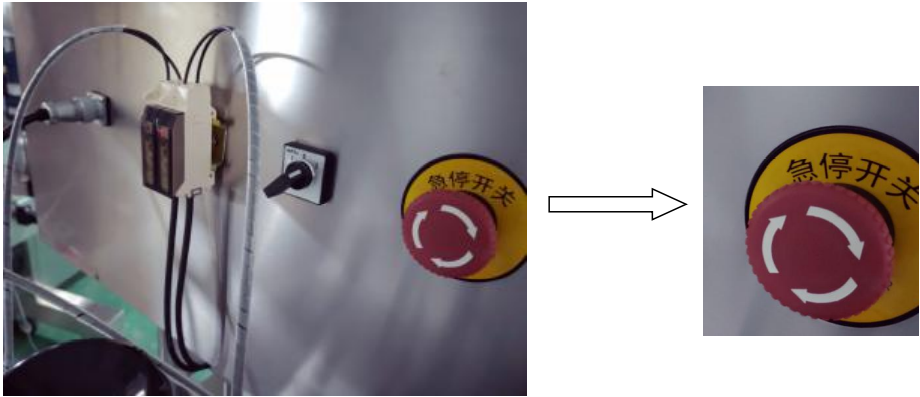

Esimeni esiphuthumayo, inkinobho yokumisa isimo esiphuthumayo ivumela umshini ukuthi umiswe ngokushesha, kugcinwe opharetha ephephile.

Isakhiwo

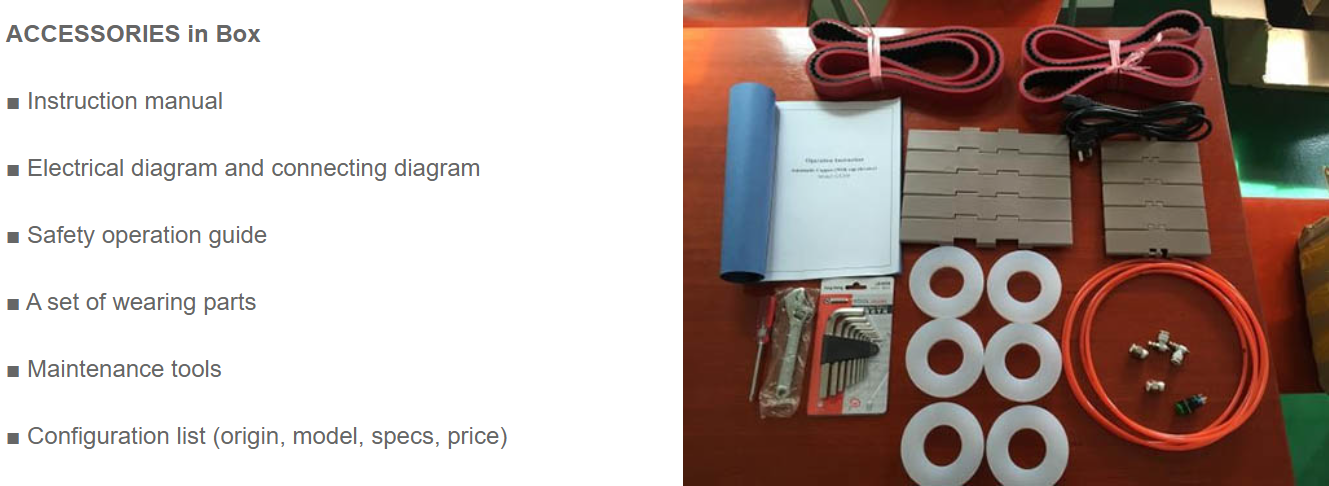

IZISEKELO EZIHLANGANISIWE EBHOKISINI

■ Incwadi yeziqondiso

■ Umdwebo kagesi nomdwebo wokuxhuma

■ Umhlahlandlela wokusebenza ngokuphepha

■ Iqoqo lezingxenye zokugqoka

■ Amathuluzi okunakekela

■ Uhlu lokucushwa (imvelaphi, imodeli, imininingwane, intengo)

Isikhathi sokuthumela: May-23-2022