Ividiyo

Isigcwalisi se-auger esipakisha phezulu

I-Shanghai Tops-group ingumkhiqizi womshini wokupakisha we-auger. Sinomthamo omuhle wokukhiqiza kanye nobuchwepheshe obuphambili be-auger powder filler. Sinelungelo lobunikazi lokubukeka kwesigcwalisi se-servo auger.

Ngaphezu kwalokho, isikhathi sethu sokukhiqiza esiyizinsuku eziyi-7 kuphela ekwakhiweni okujwayelekile.

Ngaphezu kwalokho, sinekhono lokwenza ngokwezifiso isigcwalisi se-auger ngokwesidingo sakho. Singakhiqiza i-auger filler ngokusekelwe emdwebeni wakho wokuklama kanye nelogo yakho noma imininingwane yenkampani kulebula yomshini. Futhi singahlinzeka ngezingxenye zokugcwalisa i-auger. Uma unokucushwa kwento, singasebenzisa nohlobo oluthile.

Ubuchwepheshe obubalulekile bokugcwalisa i-servo auger

■ I-Servo motor: Sisebenzisa i-Taiwan brand Delta servo motor ukulawula i-auger, ukuze sifinyelele ukunemba okuphezulu kokugcwalisa isisindo. Ibhrendi ingaqokwa.

I-servomotor iyi-actuator ejikelezayo noma i-actuator yomugqa evumela ukulawula okunembile kokuma kwe-angular noma umugqa, isivinini kanye nokusheshisa. Iqukethe injini efanelekile ehlanganiswe nenzwa ukuze uthole impendulo yendawo. Futhi idinga isilawuli esiyinkimbinkimbi, ngokuvamile imojuli ezinikele eklanyelwe ukusetshenziswa nama-servomotor.

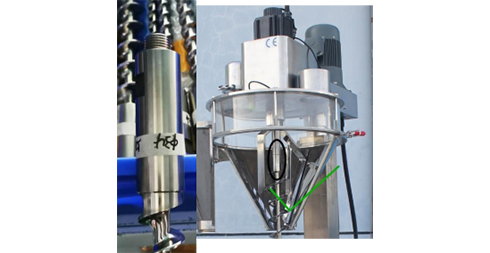

■ Izingxenye ezimaphakathi: Izingxenye ezimaphakathi ze-auger ziyingxenye ebaluleke kakhulu yesigcwalisi se-auger.

Senza umsebenzi omuhle ezingxenyeni ezimaphakathi, ukucubungula ukunemba nokuhlanganisa. Ukunemba kokucubungula nokuhlanganisa akubonakali ngeso lenyama futhi akunakuqhathaniswa ngokunembile, kodwa kuzovela ngesikhathi sokusebenzisa.

■ Ukugxila okuphezulu: Ukunemba ngeke kube phezulu uma kungekho ukugxila okuphezulu ku-auger naku-shaft.

Sisebenzisa i-brand shaft edumile emhlabeni wonke phakathi kwe-auger ne-servo motor.

■ I-Servo motor: Sisebenzisa i-Taiwan brand Delta servo motor ukulawula i-auger, ukuze sifinyelele ukunemba okuphezulu kokugcwalisa isisindo. Ibhrendi ingaqokwa.

I-servomotor iyi-actuator ejikelezayo noma i-actuator yomugqa evumela ukulawula okunembile kokuma kwe-angular noma umugqa, isivinini kanye nokusheshisa. Iqukethe injini efanelekile ehlanganiswe nenzwa ukuze uthole impendulo yendawo. Futhi idinga isilawuli esiyinkimbinkimbi, ngokuvamile imojuli ezinikele eklanyelwe ukusetshenziswa nama-servomotor.

■ Izingxenye ezimaphakathi: Izingxenye ezimaphakathi ze-auger ziyingxenye ebaluleke kakhulu yesigcwalisi se-auger.

Senza umsebenzi omuhle ezingxenyeni ezimaphakathi, ukucubungula ukunemba nokuhlanganisa. Ukunemba kokucubungula nokuhlanganisa akubonakali ngeso lenyama futhi akunakuqhathaniswa ngokunembile, kodwa kuzovela ngesikhathi sokusebenzisa.

■ Ukwenza imishini enembile: Sisebenzisa umshini wokugaya ukuze sigaye usayizi omncane we-auger, okwenza i-auger ibe namabanga afanayo kanye nokuma okunembe kakhulu.

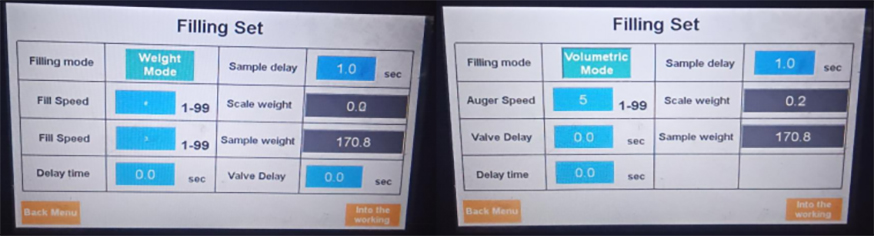

■ Izindlela zokugcwalisa ezimbili: Ingashintshwa phakathi kwemodi yesisindo nemodi yevolumu.

Imodi yevolumu:

Ivolumu yempushana eyehliswa ngesikulufu ukujika umzuliswano owodwa ilungisiwe. Isilawuli sizobala ukuthi mangaki amajika okujika isikulufu ukuze sifinyelele isisindo sokugcwalisa okuqondiwe.

Imodi yesisindo:

Kukhona iseli yomthwalo ngaphansi kwepuleti lokugcwalisa ukukala isisindo sokugcwalisa ngesikhathi.

Ukugcwaliswa kokuqala kuyashesha futhi kugcwalisa ngobuningi ukuze uthole u-80% wesisindo sokugcwalisa okuhlosiwe.

Ukugcwaliswa kwesibili kuhamba kancane futhi kunembile ukuze kugcwalise amanye ama-20% ngokwesisindo sokugcwalisa okufika ngesikhathi.

intengo yomshini wokugcwalisa i-auger

Chofoza lapha ukuze uthole inani lokugcwalisa i-auger noma isigcwalisi se-auger esithengiswayo.

Uhlobo lomshini wokugcwalisa i-Auger

I-Semi-automatic Auger Filler

I-semi-automatic auger filler ifanele ukugcwalisa isivinini esiphansi. Ngoba idinga opharetha ukuthi abeke amabhodlela epuletini ngaphansi kwesigcwalisi bese ehambisa amabhodlela ngemuva kokugcwalisa ngesandla. Ingakwazi ukuphatha kokubili ibhodlela nephakethe lesikhwama. I-hopper inenketho yensimbi engagqwali egcwele. Futhi inzwa ingakhethwa phakathi kwenzwa yemfoloko yokulungisa kanye nenzwa ye-photoelectric. Ungathola i-auger filler encane kanye nemodeli ejwayelekile kanye nemodeli yezinga eliphezulu yokugcwalisa i-auger yempushana kithi.

| Imodeli | I-TP-PF-A10 | I-TP-PF-A11 | I-TP-PF-A14 |

| Isistimu yokulawula | I-PLC nesikrini sokuthinta | I-PLC nesikrini sokuthinta | I-PLC nesikrini sokuthinta |

| I-Hopper | 11L | 25L | 50L |

| Ukupakisha Isisindo | 1-50g | 1 - 500 g | 10-5000g |

| Ukulinganisa isisindo | Nge-auger | Nge-auger | Nge-auger |

| Isisindo Impendulo | Ngesilinganiso esingaxhunyiwe ku-inthanethi (esithombeni) | Ngesilinganiso esingaxhunyiwe ku-inthanethi (esithombeni) | Ngesilinganiso esingaxhunyiwe ku-inthanethi (esithombeni) |

| Ukunemba kokupakisha | ≤ 100g, ≤±2% | ≤ 100g, ≤±2%; 100 – 500g, ≤±1% | ≤ 100g, ≤±2%; 100 - 500g, ≤±1%; ≥500g,≤±0.5% |

| Isivinini sokugcwalisa | 40 - 120 izikhathi ngomzuzu | 40 - 120 izikhathi ngomzuzu | 40 - 120 izikhathi ngomzuzu |

| Ukunikezwa kwamandla kagesi | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Amandla Aphelele | 0.84KW | 0.93 kW | 1.4KW |

| Isisindo Esiphelele | 90kg | 160kg | 260kg |

| Ubukhulu Sebonke | 590×560×1070mm | 800×790×1900mm | 1140×970×2200mm |

I-Semi-automaticI-Auger Fillernge-Pouch Clamp

Le semi-automatici-auger fillernge-pouch clamp ilungele ukugcwaliswa kwesikhwama. I-clamp yesikhwama izobamba isikhwama ngokuzenzakalelayo ngemva kokunyathela i-pedal plate. Izozikhulula isikhwama ngokuzenzakalelayo ngemva kokugcwalisa. I-TP-PF-B12 inepuleti lokuphakamisa nokuwa kwesikhwama ngesikhathi sokugcwalisa ukuze kuncishiswe iphutha lothuli nesisindo ngoba imodeli enkulu. Lapho i-powder ikhipha isuka ekugcineni kwesigcwali iye phansi kwesikhwama, amandla adonsela phansi azoholela iphutha ngoba kukhona iseli lomthwalo elithola isisindo sesikhathi sangempela. Ipuleti liphakamisa isikhwama ukuze ishubhu lokugcwalisa linamathele esikhwameni. Futhi ipuleti iwela kancane ngesikhathi sokugcwalisa.

| Imodeli | I-TP-PF-A11S | I-TP-PF-A14S | I-TP-PF-B12 |

| Isistimu yokulawula | I-PLC nesikrini sokuthinta | I-PLC nesikrini sokuthinta | I-PLC nesikrini sokuthinta |

| I-Hopper | 25L | 50L | 100L |

| Ukupakisha Isisindo | 1 - 500 g | 10-5000g | 1kg - 50kg |

| Ukulinganisa isisindo | Ngeseli yokulayisha | Ngeseli yokulayisha | Ngeseli yokulayisha |

| Isisindo Impendulo | Online isisindo impendulo | Online isisindo impendulo | Online isisindo impendulo |

| Ukunemba kokupakisha | ≤ 100g, ≤±2%; 100 – 500g, ≤±1% | ≤ 100g, ≤±2%; 100 - 500g, ≤±1%; ≥500g,≤±0.5% | 1 – 20kg, ≤±0.1-0.2%, >20kg, ≤±0.05-0.1% |

| Isivinini sokugcwalisa | 40 - 120 izikhathi ngomzuzu | 40 - 120 izikhathi ngomzuzu | 2– 25 izikhathi ngomzuzu |

| Ukunikezwa kwamandla kagesi | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Amandla Aphelele | 0.93 kW | 1.4KW | 3.2 KW |

| Isisindo Esiphelele | 160kg | 260kg | 500kg |

| Ubukhulu Sebonke | 800×790×1900mm | 1140×970×2200mm | 1130×950×2800mm |

Uhlobo lomugqa oluzenzakalelayoI-Auger Fillerngoba Amabhodlela

Uhlobo lomugqa oluzenzakalelayoi-auger fillerkusebenza ekugcwaliseni ibhodlela lempushana. Ingaxhunywa ne-powder feeder, i-powder mixer, umshini we-capping kanye nomshini wokulebula ukuze yakhe umugqa wokupakisha ozenzakalelayo. I-conveyor iletha amabhodlela ngaphakathi futhi isivalo sebhodlela sibamba amabhodlela emuva ukuze umnikazi webhodlela akwazi ukuphakamisa ibhodlela ngaphansi kwesigcwalisi. I-conveyor ihambisa amabhodlela phambili ngemva kokugcwalisa ngokuzenzakalelayo. Ingakwazi ukuphatha ibhodlela losayizi abahlukene emshinini owodwa futhi ifanele umsebenzisi onamaphakheji wobukhulu obukodwa.

Ukumisa insimbi engagqwali kanye ne-hopper yensimbi engenasici ngokuphelele uyazikhethela. Kunezinhlobo ezimbili zezinzwa ezitholakalayo. Futhi kungenziwa ngokwezifiso ukwengeza umsebenzi wokukala ku-inthanethi ukuze kuzuzwe ukunemba okuphezulu kakhulu.

| Imodeli | I-TP-PF-A21 | I-TP-PF-A22 |

| Isistimu yokulawula | I-PLC nesikrini sokuthinta | I-PLC nesikrini sokuthinta |

| I-Hopper | 25L | 50L |

| Ukupakisha Isisindo | 1 - 500 g | 10-5000g |

| Ukulinganisa isisindo | Nge-auger | Nge-auger |

| Isisindo Impendulo | ≤ 100g, ≤±2%; 100 – 500g, ≤±1% | ≤ 100g, ≤±2%; 100 - 500g, ≤±1%; ≥500g,≤±0.5% |

| Ukunemba kokupakisha | 40 - 120 izikhathi ngomzuzu | 40 - 120 izikhathi ngomzuzu |

| Isivinini sokugcwalisa | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Amandla Aphelele | 1.2 KW | 1.6 kW |

| Isisindo Esiphelele | 160kg | 300kg |

| Ubukhulu Sebonke | 1500×760×1850mm | 2000×970×2300mm |

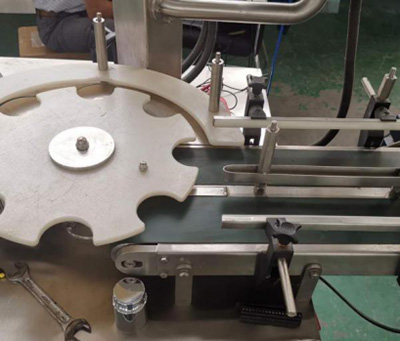

I-Rotary AutomaticI-Auger Filler

I-Rotaryi-auger fillerisetshenziselwa ukugcwalisa i-powder emabhodleleni ngesivinini esikhulu. Lolu hlobo lokugcwalisa i-auger lufanele ikhasimende elinebhodlela likasayizi owodwa noma amabili kuphela ngoba isondo lebhodlela likwazi ukuphatha ububanzi owodwa kuphela. Kodwa-ke, ukunemba nesivinini kungcono kunokugcwalisa uhlobo lomugqa we-auger. Ngaphezu kwalokho, uhlobo lwe-rotary lunomsebenzi we-inthanethi wokukala kanye nokwenqaba. I-filler izogcwalisa i-powder ngokusho kwesisindo sokugcwalisa isikhathi sangempela, futhi umsebenzi wokwenqaba uzobona futhi ukhiphe isisindo esingafanelekile.

Ikhava yomshini uyazikhethela.

| Imodeli | I-TP-PF-A31 | I-TP-PF-A32 |

| Isistimu yokulawula | I-PLC nesikrini sokuthinta | I-PLC nesikrini sokuthinta |

| I-Hopper | 35L | 50L |

| Ukupakisha Isisindo | 1-500g | 10-5000g |

| Ukulinganisa isisindo | Nge-auger | Nge-auger |

| Usayizi wesitsha | Φ20~100mm ,H15~150mm | Φ30~160mm ,H50~260mm |

| Ukunemba kokupakisha | ≤ 100g, ≤±2% 100 – 500g, ≤±1% | ≤ 100g, ≤±2%; 100 – 500g, ≤±1% ≥500g,≤±0.5% |

| Isivinini sokugcwalisa | 20 - 50 izikhathi ngomzuzu | 20 - 40 izikhathi ngomzuzu |

| Ukunikezwa kwamandla kagesi | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Amandla Aphelele | 1.8KW | 2.3 KW |

| Isisindo Esiphelele | 250kg | 350kg |

| Ubukhulu Sebonke | 1400*830*2080mm | 1840×1070×2420mm |

Isihlungi se-auger sekhanda esiphindwe kabili sempushana

I-double head auger filler ifanele ukugcwalisa isivinini esikhulu. Isivinini esiphezulu futhi sifinyelela ku-100bpm. Isistimu yokukala neyokwenqaba isheke ivimbela ukumoshwa komkhiqizo obizayo ngenxa yokulawula isisindo ngokunemba okuphezulu. Isetshenziswa kabanzi emgqeni wokukhiqiza impushana yobisi.

| Imodi yokuphuza | Imigqa ekabili egcwalisa isigcwalisi esinesisindo esiku-inthanethi |

| Ukugcwalisa Isisindo | 100 - 2000 g |

| Usayizi Wesitsha | Φ60-135mm; H 60-260mm |

| Ukugcwalisa Ukunemba | 100-500g, ≤±1g; ≥500g,≤±2g |

| Isivinini sokugcwalisa | Ngaphezu kwamathini ayi-100/min(#502),Ngaphezu kwamathini ayi-120/min(#300 ~ #401) |

| Ukunikezwa kwamandla kagesi | 3P AC208-415V 50/60Hz |

| Amandla Aphelele | 5.1kw |

| Isisindo Esiphelele | 650kg |

| Ukunikezwa Komoya | 6kg/cm 0.3cbm/min |

| I-Dimension Ephelele | 2920x1400x2330mm |

| Ivolumu ye-Hopper | 85L(Main) 45L (Ukusiza) |

I-Powder Packing system

Lapho i-auger filler isebenza ngomshini wokupakisha, yenza umshini wokupakisha oyimpuphu. Ingaxhunywa nomshini wokugcwalisa we-roll film sachet wokugcwalisa nokufaka uphawu, noma umshini wokupakisha we-doypack omncane kanye nomshini wokupakisha we-rotary pouch noma isikhwama esenziwe ngaphambilini.

Izici ze-Auger filler

■ Ukuvula i-auger ukuqinisekisa ukunemba kokugcwalisa okuphezulu.

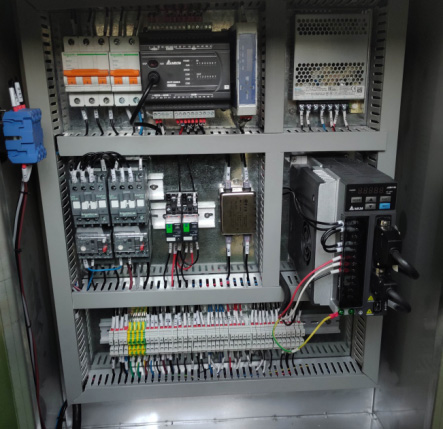

■ Ukulawula kwe-PLC ngesikrini esithintwayo, okulula ukusisebenzisa.

■ I-servo motor ishayela i-auger ukuqinisekisa ukusebenza okuzinzile.

■ Nqamula i-hopper ngokushesha kulula ukuyihlanza ngaphandle kwamathuluzi.

■ Umshini wonke uyinsimbi engagqwali engu-304.

■ Umsebenzi wokukala ku-inthanethi kanye nokulandelelwa kwengxenye kwezinto kunqoba ubunzima bokushintsha kwesisindo sokugcwalisa okubangelwa ukushintsha kokuminyana kwezinto.

■ Gcina amasethi angama-20 ezindlela zokupheka ohlelweni ukuze uwasebenzise kamuva.

■ Ukushintsha i-auger ukupakisha imikhiqizo ehlukene enesisindo esihlukene, kusukela kumpushana ocolekile kuya ezinhlayiyeni.

■ Ngomsebenzi wokwenqaba isisindo esisezingeni eliphansi.

■ Isixhumi esibonakalayo sezilimi eziningi

Uhlu Lokucushwa . A,

| Cha. | Igama | UPro. | Ibhrendi |

| 1 | I-PLC | I-Taiwan | I-DELTA |

| 2 | Isikrini sokuthinta | I-Taiwan | I-DELTA |

| 3 | I-Servo motor | I-Taiwan | I-DELTA |

| 4 | Umshayeli we-Servo | I-Taiwan | I-DELTA |

| 5 | Ukushintsha impushana |

| Schneider |

| 6 | Ukushintsha kwesimo esiphuthumayo |

| Schneider |

| 7 | Oxhumana naye |

| Schneider |

| 8 | I-Relay |

| omron |

| 9 | I-Proximity switch | Korea | Ama-Autonics |

| 10 | Inzwa yeleveli | Korea | Ama-Autonics |

B: Izesekeli

| Cha. | Igama | Ubuningi | Phawula |

| 1 | I-Fuse | 10pcs |  |

| 2 | Shintsha i-Jiggle | 1 ama-pcs | |

| 3 | 1000 g ushukela | 1 ama-pcs | |

| 4 | Isokhethi | 1 ama-pcs | |

| 5 | I-Pedal | 1 ama-pcs | |

| 6 | Ipulaki yesixhumi | 3 ama-pcs |

C: Ibhokisi lamathuluzi

| Cha. | Igama | Ubuningi | Phawula |

| 1 | I-Spanner | 2 ama-pcs |

|

| 2 | I-Spanner | 1 isethi | |

| 3 | I-screwdriver ene-slot | 2 ama-pcs | |

| 4 | Phillips screwdriver | 2 ama-pcs | |

| 5 | Imaniwali yosebenzisayo | 1 ama-pcs | |

| 6 | Uhlu lokupakisha | 1 ama-pcs |

Imininingwane yokugcwalisa i-Auger

1. I-hopper yokuzikhethela

I-hopper evulekile isigamu

Le hopper yokuhlukaniswa kwezinga i

kulula ukuvuleka nokuhlanza.

I-hopper elengayo

I-hopper ehlanganisiwe ifanelekela impushana enhle kakhulu ngoba alikho igebe engxenyeni engezansi ye-hopper

2. Imodi yokugcwalisa

Ingashintshwa phakathi kwemodi yesisindo nemodi yevolumu.

Imodi yevolumu

Ivolumu yempushana eyehliswa ngesikulufu ukujika umzuliswano owodwa ilungisiwe. Isilawuli sizobala ukuthi mangaki amajika okujika isikulufu ukuze sifinyelele isisindo sokugcwalisa okuqondiwe.

Imodi yesisindo

Kukhona iseli yomthwalo ngaphansi kwepuleti lokugcwalisa ukukala isisindo sokugcwalisa ngesikhathi.

Ukugcwaliswa kokuqala kuyashesha futhi kugcwalisa ngobuningi ukuze uthole u-80% wesisindo sokugcwalisa okuhlosiwe.

Ukugcwaliswa kwesibili kuhamba kancane futhi kunembile ukuze kugcwalise amanye ama-20% ngokwesisindo sokugcwalisa okufika ngesikhathi.

Imodi yesisindo inokunemba okuphezulu kodwa isivinini esiphansi.

Izihlungi ze-Auger ezivela kumodi eyodwa kuphela yabanye abahlinzeki: imodi yevolumu

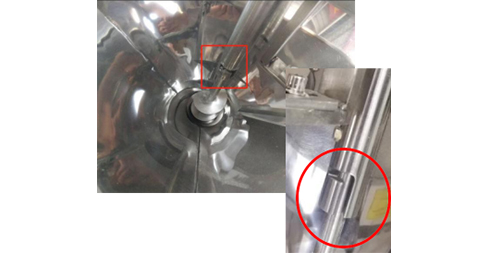

3. Indlela yokulungisa i-Auger

I-Shanghai Tops-group: Uhlobo lwesikulufu

Alikho igebe la

powder ukucasha ngaphakathi,

futhi kulula ukuhlanza

Abanye abahlinzeki: Uhlobo lwe-Hang

Kuzoba khona impushana ecashe ngaphakathi kwengxenye yokuxhuma i-hang, okunzima ukuyihlanza, futhi izoshintsha ibe yimpushana engcolisayo.

4. Isondo lesandla

Shanghai Tops-iqembu

Omunye umphakeli

Kufanelekile ukugcwalisa amabhodlela / izikhwama ezinobude obuhlukile. Vula isondo lesandla ukuze ukhuphuke futhi wehle isigcwalisi. Futhi umbambi wethu mkhulu futhi unamandla kunabanye.

5. Iyacubungula

Shanghai Tops-iqembu

Welding egcwele, kuhlanganise hopper onqenqemeni.

Kulula ukuhlanza

6. Isisekelo sezimoto

7. Indawo yomoya

Wonke umshini wenziwe nge-SS304 kufaka phakathi isisekelo nesibambi semoto, enamandla futhi esezingeni eliphezulu.

Umnikazi wemoto akuyona i-SS304.

8. Ukufinyelela okukhiphayo okubili

Amabhodlela anokugcwalisa okufanelekile

isisindo sidlula ekufinyeleleni okukodwa

Amabhodlela anokugcwalisa okungafanelekile

isisindo sizonqatshwa ngokuzenzakalelayo

kokunye ukufinyelela ebhandeni.

9. Osayizi abahlukene bokulinganisa i-auger kanye nemibhobho yokugcwalisa

Umgomo wokugcwalisa i-auger ukuthi ivolumu yempushana eyehliswa yi-auger ngokuphendula indilinga eyodwa imisiwe. Ngakho osayizi abahlukene be-auger bangasetshenziswa ebangeni lesisindo sokugcwalisa elihlukene ukuze kufinyelele ukunemba okuphezulu futhi konge isikhathi esengeziwe.

Kunamashubhu osayizi ohambisanayo we-auger kasayizi ngamunye.

isibonelo, dia. I-screw engu-38mm ifanele ukugcwalisa i-100g-250

Okulandelayo osayizi be-auger kanye nobubanzi besisindo sokugcwalisa okuhlobene

Usayizi Wendebe kanye Nobubanzi Bokugcwalisa

| Oda | Indebe | Ububanzi Bangaphakathi | Ububanzi bangaphandle | Ibanga Lokugcwalisa |

| 1 | 8# | 8 | 12 | |

| 2 | 13# | 13 | 17 | |

| 3 | 19# | 19 | 23 | 5-20g |

| 4 | 24# | 24 | 28 | 10-40 g |

| 5 | 28# | 28 | 32 | 25-70g |

| 6 | 34# | 34 | 38 | 50-120g |

| 7 | 38# | 38 | 42 | 100-250 g |

| 8 | 41# | 41 | 45 | 230-350g |

| 9 | 47# | 47 | 51 | 330-550g |

| 10 | 53# | 53 | 57 | 500-800 g |

| 11 | 59# | 59 | 65 | 700-1100 g |

| 12 | 64# | 64 | 70 | 1000-1500 g |

| 13 | 70# | 70 | 76 | 1500-2500 g |

| 14 | 77# | 77 | 83 | 2500-3500g |

| 15 | 83# | 83 | 89 | 3500-5000g |

Uma ungaqiniseki ngosayizi wakho ofanele we-auger, sicela usithinte futhi sizokukhethela usayizi ofaneleka kakhulu.

Umbukiso wefekthri yokugcwalisa i-Auger

Ukucutshungulwa kokugcwalisa kwe-Auger

I-Computer Aided Design

ukugaya

ukubhoboza

Ukuphenduka

ukugoba

ukushisela

Ukupholisha

ukubhuqa

isilawuli sikagesi

■ Faka iGrisi kancane ku-stir motor chain kanye ezinyangeni ezintathu noma ezine.

■ Umucu wokuvala ezinhlangothini zombili ze-hopper uguga cishe unyaka owodwa kamuva. Zishintshe uma kudingeka.

■ Hlanza i-hopper ngesikhathi.