I-Tops Group inikezela ngemishini ehlukahlukene yokugcwalisa i-semi-auto powder. Sinamathebula edeskithophu, amamodeli ajwayelekile, imiklamo yezinga eliphezulu anama-clamp ezikhwama, nezinhlobo zezikhwama ezinkulu. Sinomthamo omkhulu wokukhiqiza kanye nobuchwepheshe obuphambili be-auger powder filler. Sinelungelo lobunikazi ekubukekeni kwezigcwalisi ze-servo auger.

Izinhlobo Ezihlukene Zomshini Wokugcwalisa I-Semi-Auto Powder

Uhlobo Lwedeskithophu

Lena imodeli encane yetafula laselabhorethri. Yenzelwe ngqo izinto eziwuketshezi noma ezinoketshezi oluphansi njengempuphu yekhofi, ufulawa kakolweni, izinongo, iziphuzo eziqinile, imithi yezilwane, i-dextrose, imithi, izithasiselo zempushana, i-talcum powder, izibulala-zinambuzane zezolimo, udayi, njalonjalo. Lolu hlobo lomshini wokugcwalisa lungakwazi kokubili umthamo nokugcwalisa umsebenzi.

| Imodeli | I-TP-PF-A10 |

| Isistimu yokulawula | I-PLC nesikrini sokuthinta |

| I-Hopper | 11L |

| Ukupakisha Isisindo | 1-50g |

| Ukulinganisa isisindo | Nge-auger |

| Isisindo Impendulo | Ngesilinganiso esingaxhunyiwe ku-inthanethi (esithombeni) |

| Ukunemba kokupakisha | ≤ 100g, ≤±2% |

| Isivinini sokugcwalisa | 40 - 120 izikhathi ngomzuzu |

| Ukunikezwa kwamandla kagesi | 3P AC208-415V 50/60Hz |

| Amandla Aphelele | 0.84KW |

| Isisindo Esiphelele | 90kg |

| Ubukhulu Sebonke | 590×560×1070mm |

Uhlobo Olujwayelekile

Lolu hlobo lokugcwalisa lufanelekile ukugcwalisa isivinini esiphansi. Njengoba kudinga ukuthi opharetha abeke amabhodlela epuleti ngaphansi kokugcwalisa futhi asuse amabhodlela ngokomzimba ngemva kokugcwalisa. Iyakwazi ukuphatha amaphakheji webhodlela nesikhwama. I-hopper ingenziwa ngokuphelele ngensimbi engagqwali. Ngaphezu kwalokho, inzwa ingase ibe inzwa yemfoloko yokulungisa noma inzwa ye-photoelectric.

| Imodeli | I-TP-PF-A11 | I-TP-PF-A14 |

| Isistimu yokulawula | I-PLC nesikrini sokuthinta | I-PLC nesikrini sokuthinta |

| I-Hopper | 25L | 50L |

| Ukupakisha Isisindo | 1 - 500 g | 10-5000g |

| Ukulinganisa isisindo | Nge-auger | Nge-auger |

| Isisindo Impendulo | Ngesilinganiso esingaxhunyiwe ku-inthanethi (esithombeni) | Ngesilinganiso esingaxhunyiwe ku-inthanethi (esithombeni) |

| Ukunemba kokupakisha | ≤ 100g, ≤±2%; 100 – 500g, ≤±1% | ≤ 100g, ≤±2%; 100 - 500g, ≤±1%; ≥500g,≤±0.5% |

| Isivinini sokugcwalisa | 40 - 120 izikhathi ngomzuzu | 40 - 120 izikhathi ngomzuzu |

| Ukunikezwa kwamandla kagesi | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Amandla Aphelele | 0.93 kW | 1.4KW |

| Isisindo Esiphelele | 160kg | 260kg |

| Ubukhulu Sebonke | 800×790×1900mm | 1140×970×2200mm |

Nge-Pouch Clamp Type

Lesi sigcwalisi esizenzakalelayo esine-clamp yesikhwama silungele ukugcwaliswa kwesikhwama. Ngemva kokunyathela isitembu se-pedal plate, i-clamp yesikhwama izogcina isikhwama ngokuzenzakalelayo. Izokhulula isikhwama ngokuzenzakalelayo ngemva kokugcwalisa.

| Imodeli | I-TP-PF-A11S | I-TP-PF-A14S |

| Isistimu yokulawula | I-PLC nesikrini sokuthinta | I-PLC nesikrini sokuthinta |

| I-Hopper | 25L | 50L |

| Ukupakisha Isisindo | 1 - 500 g | 10-5000g |

| Ukulinganisa isisindo | Ngeseli yokulayisha | Ngeseli yokulayisha |

| Isisindo Impendulo | Online isisindo impendulo | Online isisindo impendulo |

| Ukunemba kokupakisha | ≤ 100g, ≤±2%; 100 – 500g, ≤±1% | ≤ 100g, ≤±2%; 100 - 500g, ≤±1%; ≥500g,≤±0.5% |

| Isivinini sokugcwalisa | 40 - 120 izikhathi ngomzuzu | 40 - 120 izikhathi ngomzuzu |

| Ukunikezwa kwamandla kagesi | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Amandla Aphelele | 0.93 kW | 1.4KW |

| Isisindo Esiphelele | 160kg | 260kg |

| Ubukhulu Sebonke | 800×790×1900mm | 1140×970×2200mm |

Uhlobo Lwesikhwama Esikhulu

Njengoba kunikezwe ukuthi imodeli enkulu kunazo zonke, i-TP-PF-B12 ihlanganisa ipuleti eliphakamisa futhi linciphise isikhwama ngesikhathi sokugcwalisa ukunciphisa uthuli nephutha lesisindo. Ngenxa yokuthi kukhona iseli elithwalayo elithola isisindo sesikhathi sangempela, amandla adonsela phansi azoholela ekungalungini lapho i-powder ikhishwa kusukela ekupheleni kokugcwalisa kuze kube phansi kwesikhwama. Ipuleti liphakamisa isikhwama, livumela ishubhu lokugcwalisa ukuthi linamathele kuso. Phakathi nenqubo yokugcwalisa, ipuleti iwela ngobumnene.

| Imodeli | I-TP-PF-B12 |

| Isistimu yokulawula | I-PLC nesikrini sokuthinta |

| I-Hopper | 100L |

| Ukupakisha Isisindo | 1kg - 50kg |

| Ukulinganisa isisindo | Ngeseli yokulayisha |

| Isisindo Impendulo | Online isisindo impendulo |

| Ukunemba kokupakisha | 1 – 20kg, ≤±0.1-0.2%, >20kg, ≤±0.05-0.1% |

| Isivinini sokugcwalisa | 2– 25 izikhathi ngomzuzu |

| Ukunikezwa kwamandla kagesi | 3P AC208-415V 50/60Hz |

| Amandla Aphelele | 3.2 KW |

| Isisindo Esiphelele | 500kg |

| Ubukhulu Sebonke | 1130×950×2800mm |

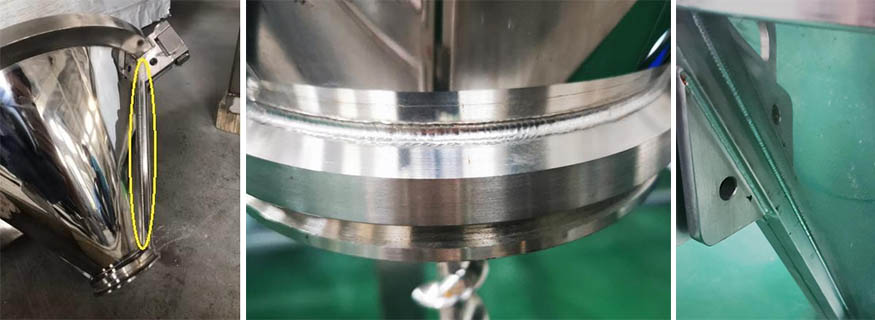

Izingxenye ezinemininingwane

I-Hopper evulwe uhhafu

Le hopper yokuhlukanisa ileveli kulula ukuyivula nokuyinakekela.

I-hopper elengayo

Ngoba asikho isikhala ngaphansi

I-A.Optional Hopper

Uhlobo lwesikulufu

Azikho izikhala zokufihla impushana ngaphakathi, futhi kulula ukuyihlanza.

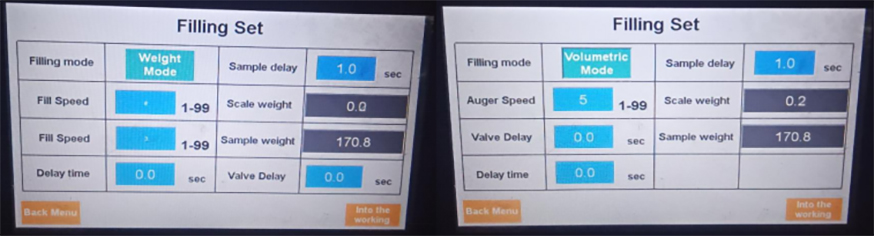

B.Imodi Yokugcwalisa

Kufanelekile ukugcwalisa amabhodlela/izikhwama ezinobude obuhlukahlukene. Vula isondo lesandla ukuze uphakamise futhi wehlise isigcwalisi. Umbambi wethu mkhulu futhi unamandla kunabanye.

Ukushisela okugcwele, okuhlanganisa unqenqema lwe-hopper, futhi kulula ukuyihlanza

Kulula ukushintsha phakathi kwezindlela zesisindo nevolumu.

Imodi yevolumu

Ivolumu yempushana iyancipha ngokuphendula isikulufu esiyindilinga esisodwa silungisiwe. Isilawuli sizonquma ukuthi zingaki ukuzungezisa isikulufu okufanele sikwenze ukuze sithole isisindo sokugcwalisa esifunekayo.

Imodi yesisindo

Ngaphansi kwepuleti yokugcwalisa kukhona iseli lomthwalo elikala isisindo sokugcwalisa ngesikhathi sangempela. Ukugcwaliswa kokuqala kuyashesha futhi kugcwaliswe ngobuningi ukuze kuzuzwe u-80% wesisindo sokugcwalisa umgomo. Ukugcwaliswa kwesibili kuhamba kancane futhi kunembile, kuhlanganisa i-20% esele ngokusekelwe kwesisindo sokugcwalisa ngesikhathi.

Imodi yesisindo inembe kakhulu, kodwa ihamba kancane.

Isisekelo semoto senziwe ngensimbi engagqwali 304.

Wonke umshini, okuhlanganisa isisekelo nesibambi sezimoto, wakhiwe nge-SS304, enamandla futhi esezingeni eliphezulu. Isibambi semoto asenziwanga nge-SS304.

C. Auger Ukulungisa Indlela

D.Isondo Lesandla

E.Inqubo

I-F.Motor Base

I-G.Air Outlet

E. Ukufinyelela kokuphumayo okubili

Amabhodlela anesisindo sokugcwalisa esifanelekayo adlula endaweni eyodwa yokufinyelela.

Amabhodlela anesisindo sokugcwalisa esingafanelekile azonqatshelwa ngokuzenzakalelayo ukufinyelela ibhande eliphambene.

F. Osayizi abahlukene bokulinganisa i-auger kanye nemibhobho yokugcwalisa

Umqondo womshini wokugcwalisa uthi inani lempushana elehliswa ngokuphendula i-auger eyodwa indilinga lilungisiwe. Njengomphumela, osayizi abaningi be-auger bangasetshenziswa kububanzi obuhlukene besisindo sokugcwalisa ukuze kuzuzwe ukunemba okwengeziwe nokonga isikhathi.

Usayizi ngamunye we-auger uneshubhu ye-auger kasayizi ohambelanayo. Njengesibonelo, isikulufu esingu-38mm sifanele ukugcwalisa u-100g–250g.